You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pile integrity test how to do it please explain ??

- Thread starter Ihsan Marwat

- Start date

Srinivasan

Prime CE

Pile Integrity Testing (PIT) is a low-strain and non- destructive integrity test method which only involves the impact from a small hand-held hammer.

How and why do this pile integrity test (PIT)......????

A pile integrity test is nothing but finding out if there are any issues in the pile which is cast in situ, as there is practically no chance to find the quality of the pile which is embedded in the earth.

In technical terms, Pile integrity test (PIT), or as ASTM D5882 refers to it as "low strain impact integrity testing of deep foundation is a widely used nondestructive test method for the evaluation of pile quality, integrity and to help estimate the unknown length of existing piles and foundations.

Pile integrity test can be either used for forensic evaluations on existing piles or quality assurance in the new construction.

The integrity test is applicable to driven concrete piles and cast-in-place piles.

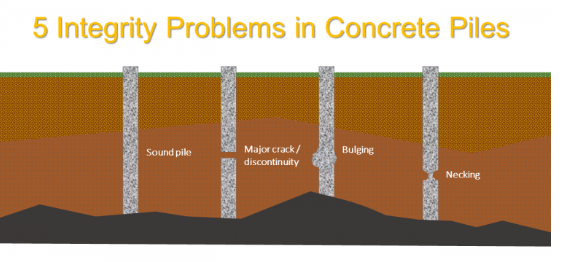

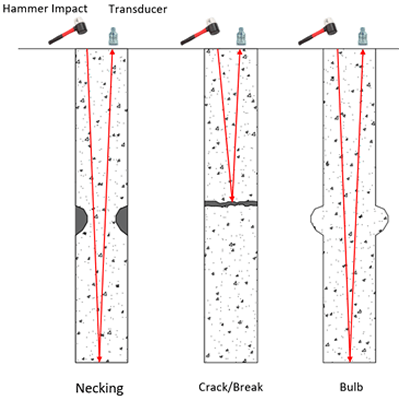

The following image provides a visual summary of major integrity issues in deep foundations.

A pile integrity test provides the following information:

- Continuity of the pile.

- Whether there are any defects like cracks etc

- Whether there is necking in the pile

- Whether there is any bulging in the pile

How the test is performed?

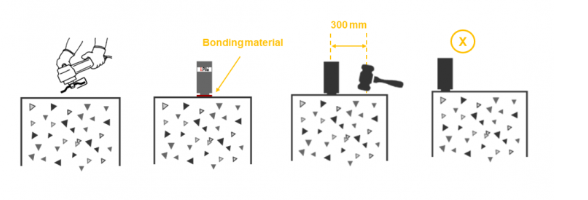

Surface preparation is the first thing to do when performing a pile integrity test. Remove top laitance etc with help of grinder so as to expose the sound concrete surface of the piles.

The acceleration sensor should be placed on concrete firmly. To do so, a couplant material should be used to attach the acceleration sensor the pile head. An impactor (usually a hand-held hammer) is used for impacting pile head; the impact should be applied axially with the pile.

Motion transducer should be capable of detecting and recording the reflected echos over the pile top. Acceleration, velocity, or displacement transducers can be used for this purpose. At the minimum, acceleration transducer should have an Analog to Digital Converter with 12 bit resolution; and a Sample Frequency of at least 25 KHz.

The location of the sensor should be selected away from the edges of the pile. The integrity testing should be performed no sooner than 7 days after casting or after concrete strength achieves at least 3/4 of its design strength, whichever occurs earlier.

The distance between the impact location and the sensor should be no larger than 300 mm. Several impacts are applied to the top of the pile.

The reflected echos are then recorded for each individual impact.

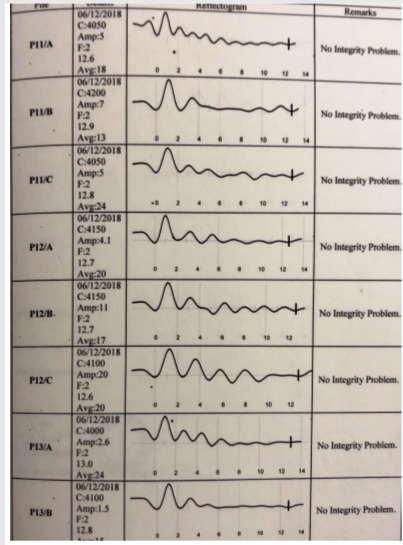

A typical reflectogram will look something shown below:

Please note that INTEGRITY TEST is to be conducted for each and every pile which are there for a particular structure and not a single pile can be skipped which kindly make note.

Hope that some basics of integrity test is clear to you.....

Apart from the INTEGRITY TESTS you also need to conduct the DYNAMIC LOADING TEST which is basically to find out the load-bearing capacity of the piles. Dynamic loading test are conducted based on the requirements of the structural engineer.

Dear Team,

Technical Specification for Pile Integrity Test

Integration testing of concrete piles are conducted for proper functioning of pile foundations. This test is carried out before construction of pile caps. Majority of cast-in-situ pile fails because of defective pile shaft necking, intrusion of foreign matters and improper toe formation due to contamination of concrete at base with soil particles, discontinuity of concrete, leaching of concrete due to high water current, improper construction method, poor quality control of concreting etc.

Cracks are developed during handling operation of precast concrete piles, this may also lead to failure of precast concrete piles. Thus, to ensure the proper placement of piles, its strength and durability, pile integration test is conducted before completion of pile caps. This integration test of piles ensures proper functioning of pile foundations without failure.

Sonic Echo Testing (IS 14893:2001) has been used successfully for checking integrity of piles after installation.

Integrity Testing of Concrete Piles

Piles integrity testing is quick and simple method and it enables number of piles to be tested in a single working day. This method provides information about continuity, defects such as cracks, necking, soil incursions, changes in cross section and approximate pile lengths (unless the pile is very long or the skin friction is too high).

Integrity tests provide an indication of soundness of concrete but they should be undertaken by persons experienced in the method and capable of interpreting the results with specific regard to piling.

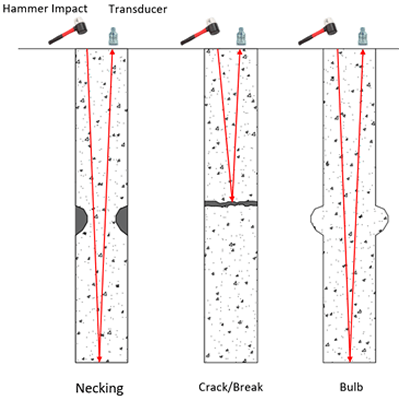

In piles integrity test, a small metal / hard rubber hammer is used to produce a light tap on the top of the pile. The shock travels down the length of the pile and is reflected back from the toe of the pile and recorded through a suitable transducer / accelerometer (also held on the top of the pile close to the point of impact)in a computer disk for subsequent analysis.

The primary shock wave which travels down the length of the shaft is reflected from the toe by change in density between the concrete and the sub strata. However, if the pile has any defects or discontinuities within its length these will set up secondary reflections which will be added to the return signal.

By a careful analysis of the captured signal and a knowledge of the conditions of the ground, age of the concrete etc. a picture of the location of such problems can be built up.

Normally more than one recording of signals is done until repeat ability of signals is achieved. In case of large diameter piles, the tests are conducted at 5-6 places to cover the entire section of the pile.

General Requirements of Piles Integrity Tests

a) Ultrasonic Pulse Velocity Test – This test is carried out at the head of the pile in order to arrive at the speed of sound propagation through the cast concrete of the pipe.

b) Penetration Test – The test is used to assess the strength of the concrete at the pile head to ensure that the pile is sufficiently cured and ready for NDT.

c) Density Testing Of Cast Cubes – In order to determine the density of concrete used each cube should be measured for density by weighing in air and water.

Limitations of Piles Integrity Tests

Technical Specification for Pile Integrity Test

Integration testing of concrete piles are conducted for proper functioning of pile foundations. This test is carried out before construction of pile caps. Majority of cast-in-situ pile fails because of defective pile shaft necking, intrusion of foreign matters and improper toe formation due to contamination of concrete at base with soil particles, discontinuity of concrete, leaching of concrete due to high water current, improper construction method, poor quality control of concreting etc.

Cracks are developed during handling operation of precast concrete piles, this may also lead to failure of precast concrete piles. Thus, to ensure the proper placement of piles, its strength and durability, pile integration test is conducted before completion of pile caps. This integration test of piles ensures proper functioning of pile foundations without failure.

Sonic Echo Testing (IS 14893:2001) has been used successfully for checking integrity of piles after installation.

Integrity Testing of Concrete Piles

Piles integrity testing is quick and simple method and it enables number of piles to be tested in a single working day. This method provides information about continuity, defects such as cracks, necking, soil incursions, changes in cross section and approximate pile lengths (unless the pile is very long or the skin friction is too high).

Integrity tests provide an indication of soundness of concrete but they should be undertaken by persons experienced in the method and capable of interpreting the results with specific regard to piling.

In piles integrity test, a small metal / hard rubber hammer is used to produce a light tap on the top of the pile. The shock travels down the length of the pile and is reflected back from the toe of the pile and recorded through a suitable transducer / accelerometer (also held on the top of the pile close to the point of impact)in a computer disk for subsequent analysis.

The primary shock wave which travels down the length of the shaft is reflected from the toe by change in density between the concrete and the sub strata. However, if the pile has any defects or discontinuities within its length these will set up secondary reflections which will be added to the return signal.

By a careful analysis of the captured signal and a knowledge of the conditions of the ground, age of the concrete etc. a picture of the location of such problems can be built up.

Normally more than one recording of signals is done until repeat ability of signals is achieved. In case of large diameter piles, the tests are conducted at 5-6 places to cover the entire section of the pile.

General Requirements of Piles Integrity Tests

- Pile shall be trimmed to cut off level or sound concrete level before the test with all laitance removed.

- The area surrounding the pile should be free from standing water and should be kept dewatered during the tests.

- The cast in situ piles should not normally be tested before 14 days of casting.

- The test piles, if available at site can be used for determination of pulse velocity and characteristic or reference signal generated. This can also be done from those piles whose depth is accurately recorded.

a) Ultrasonic Pulse Velocity Test – This test is carried out at the head of the pile in order to arrive at the speed of sound propagation through the cast concrete of the pipe.

b) Penetration Test – The test is used to assess the strength of the concrete at the pile head to ensure that the pile is sufficiently cured and ready for NDT.

c) Density Testing Of Cast Cubes – In order to determine the density of concrete used each cube should be measured for density by weighing in air and water.

Limitations of Piles Integrity Tests

- The present experience of NDT of piles is up to diameter of 1500 mm.

- This is applicable to cast in situ concrete bored and driven piles. The test cannot be conducted after provision / casting of pile cap.

- This method is not suitable for piles surrounded by water as it may not give correct results.

- It does not provide information regarding verticality or displacement (in position) of the piles.

- Local loss of cover, small intrusions or type of conditions at the base of piles are undetectable.

Attachments

safdar.imam

Newbie

can you share this safdar.imam147@gmail.comA pile integrity test is nothing but finding out if there are any issues in the pile which is cast in situ, as there is practically no chance to find the quality of the pile which is embedded in the earth.

In technical terms, Pile integrity test (PIT), or as ASTM D5882 refers to it as "low strain impact integrity testing of deep foundation is a widely used nondestructive test method for the evaluation of pile quality, integrity and to help estimate the unknown length of existing piles and foundations.

Pile integrity test can be either used for forensic evaluations on existing piles or quality assurance in the new construction.

The integrity test is applicable to driven concrete piles and cast-in-place piles.

The following image provides a visual summary of major integrity issues in deep foundations.

View attachment 3132

A pile integrity test provides the following information:

- Continuity of the pile.

- Whether there are any defects like cracks etc

- Whether there is necking in the pile

- Whether there is any bulging in the pile

How the test is performed?

Surface preparation is the first thing to do when performing a pile integrity test. Remove top laitance etc with help of grinder so as to expose the sound concrete surface of the piles.

The acceleration sensor should be placed on concrete firmly. To do so, a couplant material should be used to attach the acceleration sensor the pile head. An impactor (usually a hand-held hammer) is used for impacting pile head; the impact should be applied axially with the pile.

Motion transducer should be capable of detecting and recording the reflected echos over the pile top. Acceleration, velocity, or displacement transducers can be used for this purpose. At the minimum, acceleration transducer should have an Analog to Digital Converter with 12 bit resolution; and a Sample Frequency of at least 25 KHz.

The location of the sensor should be selected away from the edges of the pile. The integrity testing should be performed no sooner than 7 days after casting or after concrete strength achieves at least 3/4 of its design strength, whichever occurs earlier.

The distance between the impact location and the sensor should be no larger than 300 mm. Several impacts are applied to the top of the pile.

The reflected echos are then recorded for each individual impact.

View attachment 3133

A typical reflectogram will look something shown below:

View attachment 3137

Please note that INTEGRITY TEST is to be conducted for each and every pile which are there for a particular structure and not a single pile can be skipped which kindly make note.

Hope that some basics of integrity test is clear to you...... Have conducted numerous tests on piles which were used for ESR in number of ESR built by us for our company in Mumbai.

Apart from the INTEGRITY TESTS you also need to conduct the DYNAMIC LOADING TEST which is basically to find out the load-bearing capacity of the piles. Dynamic loading test are conducted based on the requirements of the structural engineer.

safdar.imam

Newbie

A Pile Integrity Test (PIT) is a non-destructive test (NDT) used in foundation engineering to check whether a pile has been constructed correctly — without cracking, voids, necking, or major defects — and to give an estimate of its length. It does not measure the load-carrying capacity.Pile integrity test, how to do it, please explain ???

Why it’s done:

- To ensure pile quality before superstructure or load testing.

- To pick up hidden defects early (cracks, voids, concrete quality issues).

- To estimate the actual length of the pile.

- You apply a small impact (light hammer blow) to the top of the pile.

- This impact creates a stress wave that travels down the pile.

- If the pile is continuous and defect-free, the wave returns from the pile’s tip at a predictable time.

- If there is a defect (crack, void, necking), part of the wave reflects earlier — which shows up in the recorded signal.

- Hand-held hammer (small metal/hard rubber)

- Accelerometer or sensor to record vibration

- Pile Integrity Tester (PIT) instrument + software to capture and analyze signals

- Adhesive material to fix sensor on pile head (e.g., petroleum jelly)

Step by Step Procedure :

1 . Prepare the Pile Head

- Make sure the top surface of the pile is:

- Clean (no dirt, loose concrete or laitance).

- Flat (levelled cut-off).

- Free of protruding steel or debris.

This ensures reliable contact with the sensor and hammer.

- Use a thin layer of adhesive (like petroleum jelly or wax).

- Attach the accelerometer firmly at a central point on the pile head.

- Ensure good contact — a thick adhesive layer can distort the data.

- Use a thin layer of adhesive (like petroleum jelly or wax).

- Attach the accelerometer firmly at a central point on the pile head.

- Ensure good contact — a thick adhesive layer can distort the data.

- Connect the accelerometer to the PIT instrument (data logger).

- Switch on the data acquisition system.

- Check settings such as sampling rate and reference wave speed based on concrete type (usually concrete’s wave velocity is known or estimated).

- Use the hammer to give light taps near the sensor location.

- Make 3–5 strikes at the same spot to get repeatable waveforms.

- The data logger captures how the pile responds over time.

- The instrument will show a time-wave signal (impact response over time).

- These signals are saved for analysis.

- More recordings improve accuracy.

This is key an engineer or technician will interpret the waveform:

- First wave travel time gives an estimate of pile length.

- voids

- cracks

- necking (reduction in cross-section)

- bulges

Signals are compared to reference data or expected waveforms.

- A proper report includes:

- Pile ID and location

- Test date/time

- Sensor and instrument settings

- Recorded waveforms

- Interpreted pile length

- Any detected anomalies and their estimated depths

- Clear conclusions on pile integrity

| Indicator in Signal | Likely Meaning |

|---|---|

| Reflection at expected time | Good integrity & correct length |

| Early reflection | Likely defect (void/crack) |

| Multiple reflections | Multiple defects or cross-section changes |

Important Practical Notes

Concrete must be sufficiently hardened before testing (often ≥7–14 days) so that the wave travels reliably.PIT does not give bearing capacity use other methods (load tests) for that.

Pile cap must not be cast before integrity testing, as the test is done at pile head.

Test limitations include inability to detect very small defects and sensitivity to soil conditions.

Indian Standard Reference

The Indian Standard IS 14893:2001 – Non-Destructive Testing of Piles provides guidelines for carrying out integrity tests, interpretation, and limitations emphasising that results must be judged by experienced engineers and may need confirmation with further testing (e.g., static load tests) if serious defects are indicated.

Attachments

Similar threads

- Replies

- 0

- Views

- 717

- Replies

- 0

- Views

- 1,442

- Replies

- 0

- Views

- 1,413