After different processes on the vacuum bottom, various grades of bitumen are produced. About 85% of them are used in road construction which is primarily penetration and viscosity bitumen.

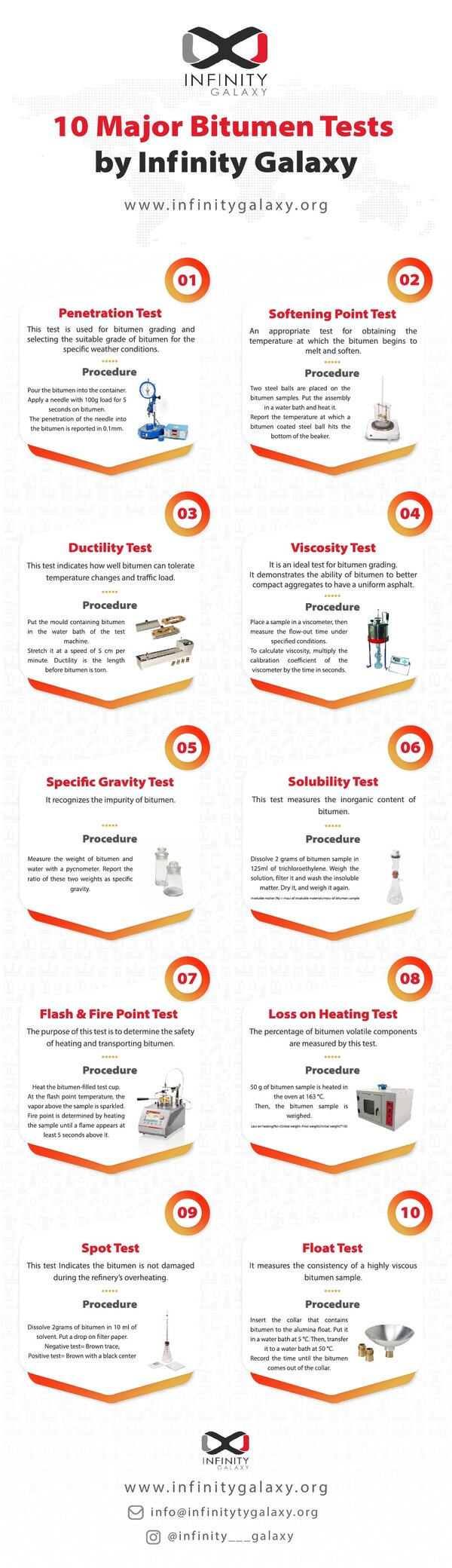

A series of tests have been designed to control their quality which is summarized in this infographicIn the laboratory of the production unit, it must be checked whether produced bitumen has the properties defined for it or not.

It is better to know that vacuum bottoms do not always have the same composition, so the chemical composition of bitumen produced from them is not always the same. Therefore, each bitumen quality test is based on physical properties.

The following are the important tests for measuring penetration bitumen quality:

- Penetration test

- Softening point

- Ductility

- Specific gravity

- Solubility

- Flash and Fire point

- Spot

For viscosity bitumen, fewer tests are used which include:

- Viscosity test at two temperatures of 60° C and 135 ° C

- Penetration

- Flash and fire point

- Solubility

- Loss on Heating (Thin Film Oven Test)

Now let's answer this question, what is the specific purpose of designing each bitumen test?

Why are bitumen tests used?

1- Classification of different types of bitumen for use in the intended climate:

The penetration test was first introduced to the industry in the early twentieth century to grade bitumen based on its hardness and softness at 25 ° C.

In this experiment, a needle with a load of 100 grams is applied to the bitumen surface for 5 seconds. The needle penetration is reported in decimilimeters (0.1 mm). Common grades of penetration bitumen include 30/40, 40/50, 50/60, 60/70, and 80/100.

Penetration grades 60/70 and 80/100 are the most widely used bitumen in road construction.

Unfortunately, this method of classification is simple but has a major weakness. Because it can not predict the behavior of bitumen at high temperatures.

The viscosity grading system was introduced to compensate for this shortcoming.

This divides the bitumen into 4 grades VG 10, VG 20, VG 30, and VG 40 based on the amount of viscosity.

Figure 1: Penetrometer

A viscometer is used to perform a viscosity test. The general procedure of these devices is to measure the passage time of a certain amount of bitumen in seconds. Multiplying this time by the coefficient of the device converts it to viscosity.

Figure 2: In order from left to right Tar viscometer, Reometer, Capillary Viscometer

2- Evaluating the consistency and stability of bitumen:

In addition to bitumen classification, penetration and viscosity tests also demonstrate the consistency of bitumen.

The softening point test also displays this property of the bitumen as the temperature rises. It determines the temperature at which the bitumen starts to melt.

Figure 3: Apparatus of softening point test

Another test performed to measure consistency is the ductility test.

In this test, bitumen is lengthened in a water bath. Suitable bitumen for road construction with a good consistency should stretch above 100 cm.

The ductility test measures the resistance of bitumen to changes in air temperature and traffic load.

The use of bitumen with proper consistency and ductility will reduce cracking and increase the asphalt lifespan.

If the bitumen sample is very viscous, then the float test is used to measure the consistency of the bitumen.

3- Measure the bitumen quality:

To have standard asphalt, we must use high-quality bitumen. It should have the following properties:- The minimum amount of inorganic impurities (permissible amount is less than 1% by weight)

- The minimum amount of volatiles (permissible amount is less than 1% by weight)

- Not overheating in the production process

Figure 4: Solubility test of bitumen

To obtain the percentage of volatiles in bitumen, the loss on heating test is used.

To perform this test, heat 50 grams of it for 5 hours at 163 ° C. The weight loss of bitumen should be less than 1%. Otherwise, the bitumen loses its adhesion during the process of preparing hot asphalt and also over time.

Sometimes overheating during bitumen production leads to cracking which reduces the elasticity of bitumen. As a result, bitumen does not act as a good binder. To detect this, the spot test is used, in which we dissolve 2 grams of bitumen in 10 ml of organic solvent. Then pour a drop of the solution on the paper and check its trace.

4- Evaluate the hazards of transport and storage:

Bitumen is a flammable substance. As a result, caution in transporting and storing it is very important. For this purpose, a flash and fire point test is designed.In this experiment, the ignition temperature of bitumen vapor materials and bitumen itself is measured. Suitable bitumen should have an ignition temperature above a certain level so ignition does not occur when preparing hot asphalt.

As a final note, I want to point out the below-attached infographic which is a brief overview of 10 major bitumen tests.