AGGREGATE IMPACT VALUE TEST

AIM: To find Impact value of the given aggregate sample.

APPARATUS

The apparatus consists of an impact-testing machine, a cylindrical measure, tamping rod, IS sieve, balance, tamping rod and oven.

PROCEDURE

The test sample consists of aggregates passing 12.5 mm sieve and retained on 10 mm sieve and dried in an oven for four hours at a temperature 1000 C to 1100 C and cooled. The aggregates are filled up to about one-third full in the cylindrical measure and tamped 25 times with rounded end of the tamping rod. Further quantity of aggregates are struck off using the tamping rod as straight edge. The net weight of the aggregates in the measure is determined to the nearest gram and this weight of the aggregates is used for carrying out duplicate test on the same material. The impact machine is placed with its bottom plate fiat on the floor so that the hammer guide columns are vertical. The cup is fixed firmly in position on the base of the machine and the whole of the test sample from the cylindrical measure is transferred to the cup and compacted by tamping with 25 strokes.

The hammer is raised until its lower face is 38 cm above the upper surface of the aggregates in the cup, and allowed to fall freely on the aggregates. The test sample is subjected to a total of 15 such blows, each being delivered at an interval of not less than one second. The crushed aggregate is then removed from the cup and the whole of it sieved on the 2.36 mm sieve until no further significant amount passes. The fraction passing the sieve is weighed accurate to 0.1 g. The fraction retained on the sieve is also weighed and if the total weight of the fractions passing and retained on the sieve is added, it should not be less than the original weight of the specimen by more than one gram; if the total weight is less than the original by over one gram, the result should be discarded and a fresh test made.

The above test is repeated on fresh aggregate sample.

RESULT:

The mean of the two results is reported as the aggregate impact value of the specimen to the nearest whole number.

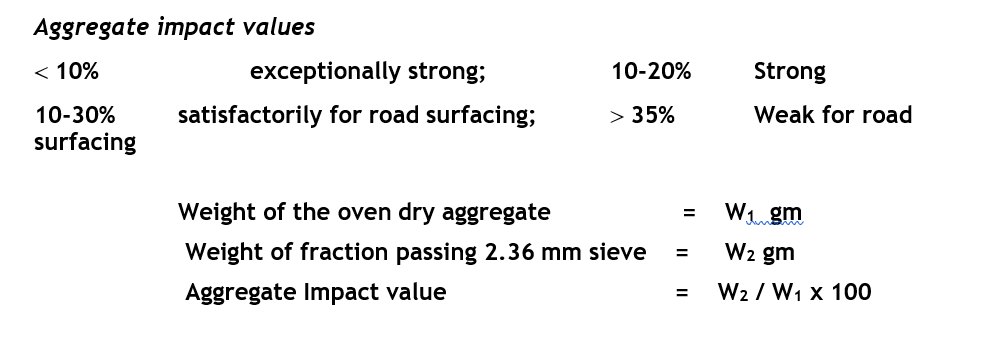

Aggregate impact value is to classify the stones in respect of their toughness property as indicated below:

Aggregate impact values

< 10% exceptionally strong;

10-20% Strong

10-30% satisfactorily for road surfacing;

> 35% Weak for road surfacing

APPLICATIONS OF AGGREGATE IMPACT VALUE

The aggregate impact test is considered to be an important test to access the suitability of aggregates as regards the toughness for use in pavement construction. It has been found that for majority of aggregates, the aggregate crushing and aggregate impact values are numerically similar within close limits. But in the case of fine grained highly siliceous aggregate which are less resistant to impact than to crushing. The aggregate impact values are higher (on the average, by about 5) than the aggregate crushing values.

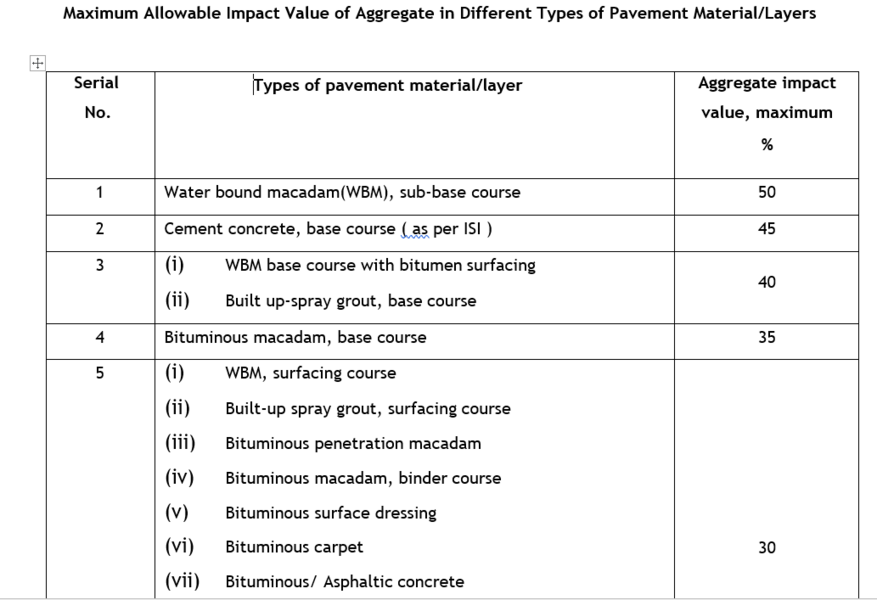

Various agencies have specified the maximum permissible aggregate impact values for the different types of pavements, those recommended by the Indian Roads congress are given in Table 1.

For deciding the suitability of soft aggregates in base course construction, this test has been commonly used. A modified impact test is also often carried out in the case of soft aggregates to fine the wet impact value after soaking the test sample.

AIM: To find Impact value of the given aggregate sample.

APPARATUS

The apparatus consists of an impact-testing machine, a cylindrical measure, tamping rod, IS sieve, balance, tamping rod and oven.

PROCEDURE

The test sample consists of aggregates passing 12.5 mm sieve and retained on 10 mm sieve and dried in an oven for four hours at a temperature 1000 C to 1100 C and cooled. The aggregates are filled up to about one-third full in the cylindrical measure and tamped 25 times with rounded end of the tamping rod. Further quantity of aggregates are struck off using the tamping rod as straight edge. The net weight of the aggregates in the measure is determined to the nearest gram and this weight of the aggregates is used for carrying out duplicate test on the same material. The impact machine is placed with its bottom plate fiat on the floor so that the hammer guide columns are vertical. The cup is fixed firmly in position on the base of the machine and the whole of the test sample from the cylindrical measure is transferred to the cup and compacted by tamping with 25 strokes.

The hammer is raised until its lower face is 38 cm above the upper surface of the aggregates in the cup, and allowed to fall freely on the aggregates. The test sample is subjected to a total of 15 such blows, each being delivered at an interval of not less than one second. The crushed aggregate is then removed from the cup and the whole of it sieved on the 2.36 mm sieve until no further significant amount passes. The fraction passing the sieve is weighed accurate to 0.1 g. The fraction retained on the sieve is also weighed and if the total weight of the fractions passing and retained on the sieve is added, it should not be less than the original weight of the specimen by more than one gram; if the total weight is less than the original by over one gram, the result should be discarded and a fresh test made.

The above test is repeated on fresh aggregate sample.

RESULT:

The mean of the two results is reported as the aggregate impact value of the specimen to the nearest whole number.

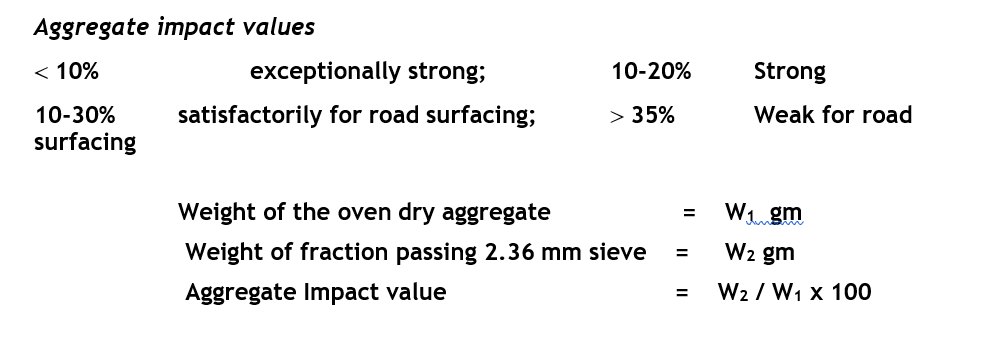

Aggregate impact value is to classify the stones in respect of their toughness property as indicated below:

Aggregate impact values

< 10% exceptionally strong;

10-20% Strong

10-30% satisfactorily for road surfacing;

> 35% Weak for road surfacing

APPLICATIONS OF AGGREGATE IMPACT VALUE

The aggregate impact test is considered to be an important test to access the suitability of aggregates as regards the toughness for use in pavement construction. It has been found that for majority of aggregates, the aggregate crushing and aggregate impact values are numerically similar within close limits. But in the case of fine grained highly siliceous aggregate which are less resistant to impact than to crushing. The aggregate impact values are higher (on the average, by about 5) than the aggregate crushing values.

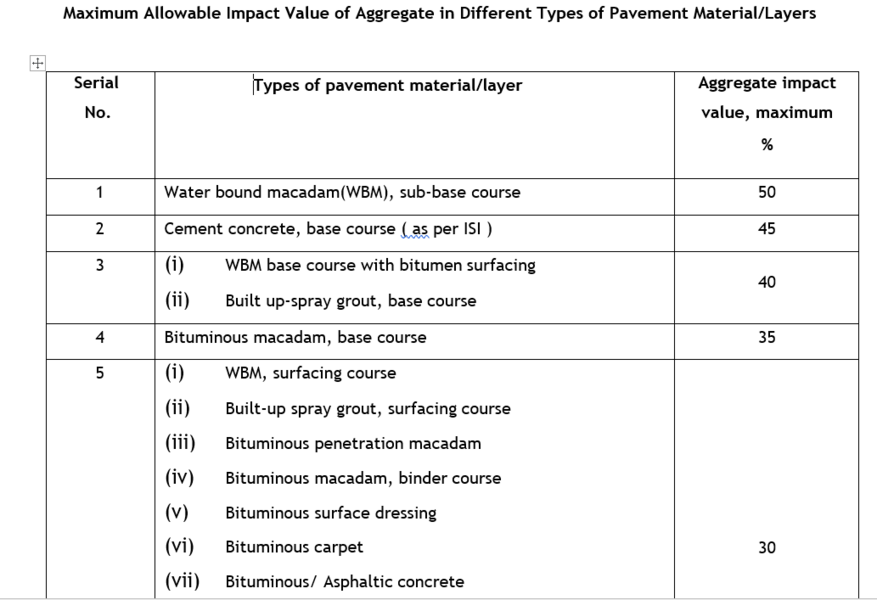

Various agencies have specified the maximum permissible aggregate impact values for the different types of pavements, those recommended by the Indian Roads congress are given in Table 1.

For deciding the suitability of soft aggregates in base course construction, this test has been commonly used. A modified impact test is also often carried out in the case of soft aggregates to fine the wet impact value after soaking the test sample.