Bitumen Penetration Test

Penetration test is the most common test to grade bitumen according to its hardness and consistency. It determines the softness or hardness of a sample of bitumen by measuring how deep a certain needle can penetrate the bitumen under controlled test conditions. Penetration test is an essential test in road construction, where the appropriate grade of bitumen will result in long-lasting, weather-resistant roads.

Every step of the penetration test process—preparation to result—in simple language and clear steps.

Purpose of the Penetration Test

Bitumen: A Quick Background

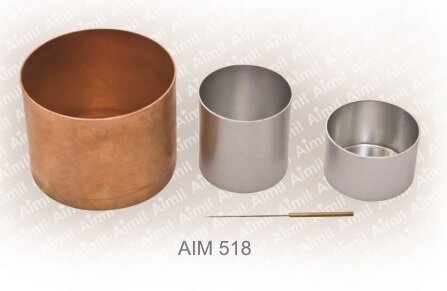

Apparatus Needed

For conducting the test for penetration, the following apparatus are required:

After the sample is prepared, the test agent for penetration is conducted as follows:

The method complies with IS 1203:1978, which prescribes standardized procedures for penetration test on bitumen.

Precautions to Ensure Accuracy

Penetration test is an essential step in controlling the quality of bitumen. Based on how deep a needle penetrates a sample of bitumen under test conditions, engineers can quickly decide whether the bitumen in question is well-suited to various environmental and construction requirements. It's easy, quick, and very enlightening when conducted with care.

Penetration test is the most common test to grade bitumen according to its hardness and consistency. It determines the softness or hardness of a sample of bitumen by measuring how deep a certain needle can penetrate the bitumen under controlled test conditions. Penetration test is an essential test in road construction, where the appropriate grade of bitumen will result in long-lasting, weather-resistant roads.

Every step of the penetration test process—preparation to result—in simple language and clear steps.

Purpose of the Penetration Test

- The primary objective is to find out the grade of bitumen based on its consistency measure.

- It assists engineers in choosing appropriate bitumen for various climates and pavement types.

- Soft bitumen indicates higher penetration, whereas harder bitumen means lower penetration.

Bitumen: A Quick Background

- Bitumen is a sticky, black product resulting from crude oil refining.

- Based on the method of refining (distillation, solvent extraction, etc.), bitumen may differ in hardness and temperature characteristics.

- Good quality bitumen must:

- Not soften in warm climates.

- Not become brittle in cold climates.

- Have the correct viscosity during compaction and mixing.

Apparatus Needed

For conducting the test for penetration, the following apparatus are required:

- Penetrometer – Standard needle assembly and dial gauge come with it.

- Standard Needle – Carefully sized (generally 1 mm diameter) and has a weight of 100 g along with the loading device.

- Metal Container – To store the molten bitumen sample.

- Water Bath – Keeps test temperature at 25°C.

- Thermometer – For testing water bath temperature.

- Benzene – For cleaning the needle after every trial.

- Heat the bitumen until its pouring consistency (above the softening point).

- Stir well to eliminate any air bubbles.

- Pour into a metal container, with the bitumen depth being not less than 15 mm greater than the anticipated penetration.

- Condition the sample at room temperature for 90 minutes.

- Prepare a water bath at 25°C and leave it for another 90 minutes for equitable conditioning.

After the sample is prepared, the test agent for penetration is conducted as follows:

- Position the container holding the bitumen sample beneath the needle of the penetrometer.

- Start lowering the needle until it is lightly touching the surface of the bitumen.

- Adjust the dial gauge to zero or note the original reading.

- Let go of the needle and allow it to penetrate for a precise 5 seconds.

- Observe the last dial reading, which is the depth of penetration in tenths of a millimeter.

- Test three times, at least 10 mm apart, on the same test piece.

- Clean the needle with benzene between trials.

- Compute the mean of the three readings – this is the ultimate penetration value.

- Unit of measurement is tenths of a millimeter. Therefore, a reading of 65 represents penetration of 6.5 mm.

- Example Grades:

- 30/40 grade → 3.0 to 4.0 mm penetration

- 80/100 grade → 8.0 to 10.0 mm penetration

- Increased penetration → softer bitumen (used in cold climate)

- LOWER penetration → harder bitumen (used in hot climate)

The method complies with IS 1203:1978, which prescribes standardized procedures for penetration test on bitumen.

Precautions to Ensure Accuracy

- The sample should be dust-free or free from impurities.

- The container should not be agitated during the test.

- The needle should be washed and dried before taking every reading.

- Proper temperature (25°C) and precise needle weight are essential.

- Don't apply this test to soft materials such as tar or cutbacks – they are subjected to viscosity tests.

- In warm climates, lower penetration value (30/40) bitumen is utilized to prevent melting.

- Whereas in cold climates, more penetration grade (180/200) is used to avoid brittleness cracking.

- For spray use, high penetration bitumen is utilized.

Penetration test is an essential step in controlling the quality of bitumen. Based on how deep a needle penetrates a sample of bitumen under test conditions, engineers can quickly decide whether the bitumen in question is well-suited to various environmental and construction requirements. It's easy, quick, and very enlightening when conducted with care.