AIM: To find the flakiness index of the given aggregate sample.

APPARATUS:

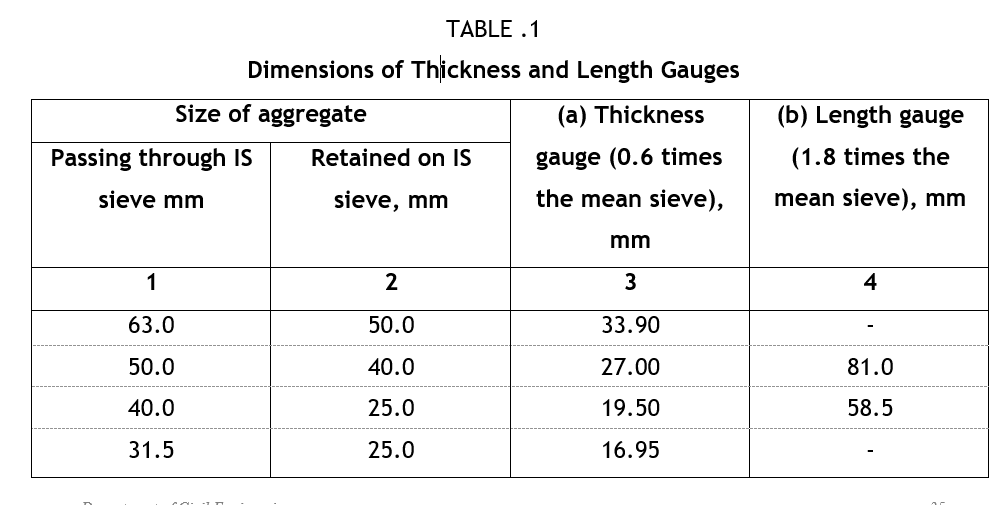

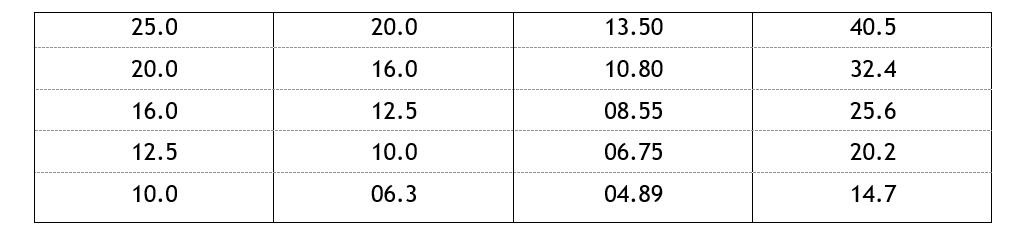

The apparatus consists of a standard thickness gauge, IS sieves of sizes 63,50,40,31,5,25,20,16,12.5,10 and 6.3 mm and a balance to weigh the samples.

PROCEDURE:

The sample is sieve with the sieves mentioned in Table 1. A minimum of 200 pieces of each fraction to be tested are taken and weighed = W1 g.

In order to separate flaky materials, each fraction is then gauged for thickness on a thickness gauge or in bulk on sieves having elongated slots.

The width of the slot should be of the dimensions specified in column (3) of Table 15.1 for the appropriate size of material. The amount of flaky material passing the gauge is weighed to an accuracy of at least 0.1 percent of the test sample.

CALCULATION AND RESULT:

In order to calculate the flakiness index of the entire sample of aggregates first the weight of each fraction of aggregate passing and retained on the specified set of sieves is noted. As an example let 200 pieces of the aggregate pasing 50 mm sieve and retained on 50 mm sieve be= W1 g. Each of the particles from this fraction of aggregate is tried to be passed through the slot of the specified thickness of the thickness gauge; in this example the width of the appropriate gauge of the thickness gauge is 27.0 mm gauge.

Let the weight of the flaky material passing this gauge be X1 g. Similarly the weights of the fractions passing and retained the specified sieves, X1, X2, X3, etc., are weighed and the total weight X1+ X2 +X3 +… = Xg is found.

Also the weights of materials passing each of the specified thickness gauge are found = W1, W2, W3… and the total weight of material passing the different thickness gauges = W1+ W2 +W3 + … = Wg is found.

Then the flakiness index is the total weight of the flaky material passing the various thickness gauges expressed as a percentage of the total weight of the sample gauged.

Flakiness Index = (Xg / Wg) x 100%

APPARATUS:

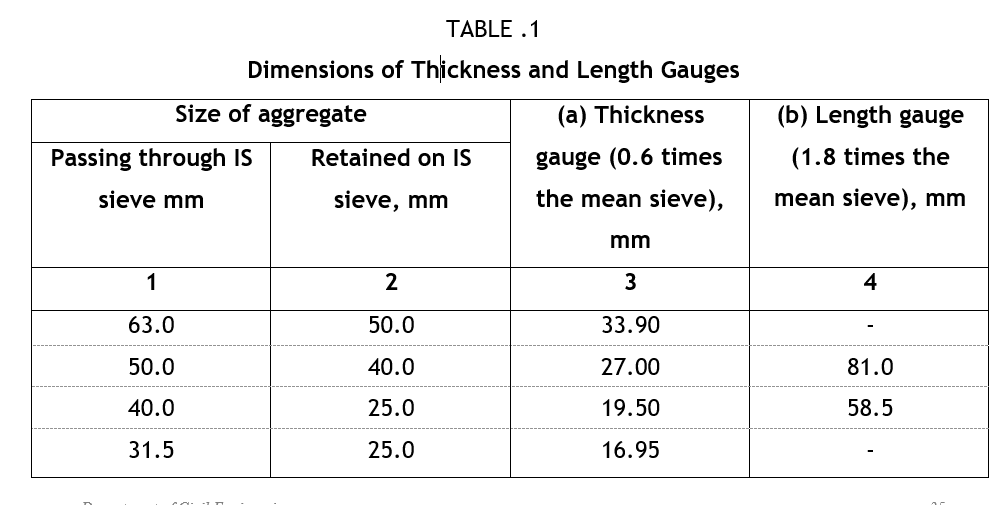

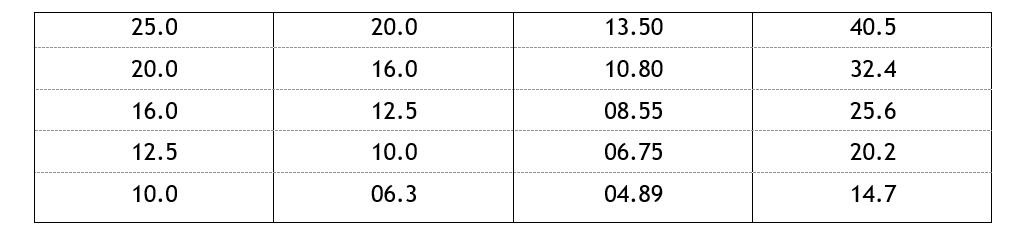

The apparatus consists of a standard thickness gauge, IS sieves of sizes 63,50,40,31,5,25,20,16,12.5,10 and 6.3 mm and a balance to weigh the samples.

PROCEDURE:

The sample is sieve with the sieves mentioned in Table 1. A minimum of 200 pieces of each fraction to be tested are taken and weighed = W1 g.

In order to separate flaky materials, each fraction is then gauged for thickness on a thickness gauge or in bulk on sieves having elongated slots.

The width of the slot should be of the dimensions specified in column (3) of Table 15.1 for the appropriate size of material. The amount of flaky material passing the gauge is weighed to an accuracy of at least 0.1 percent of the test sample.

CALCULATION AND RESULT:

In order to calculate the flakiness index of the entire sample of aggregates first the weight of each fraction of aggregate passing and retained on the specified set of sieves is noted. As an example let 200 pieces of the aggregate pasing 50 mm sieve and retained on 50 mm sieve be= W1 g. Each of the particles from this fraction of aggregate is tried to be passed through the slot of the specified thickness of the thickness gauge; in this example the width of the appropriate gauge of the thickness gauge is 27.0 mm gauge.

Let the weight of the flaky material passing this gauge be X1 g. Similarly the weights of the fractions passing and retained the specified sieves, X1, X2, X3, etc., are weighed and the total weight X1+ X2 +X3 +… = Xg is found.

Also the weights of materials passing each of the specified thickness gauge are found = W1, W2, W3… and the total weight of material passing the different thickness gauges = W1+ W2 +W3 + … = Wg is found.

Then the flakiness index is the total weight of the flaky material passing the various thickness gauges expressed as a percentage of the total weight of the sample gauged.

Flakiness Index = (Xg / Wg) x 100%