When it comes to a formwork components in critical area where de-shuttering becomes a tedious task specially in case of aluminium formwork or any engineered formwork, normally a grease is order namely yellow batata grease for applying on formwork surface for ease in de-shuttering / stripping.

As the specifications are not provided along with the product name, this will lead to variety of grease supply, some with a good quality and some with bad quality in terms of its properties. Grease is supplied in Kg / MT and the applied surface coverage is calculated base on the volume.

During construction we might come across a situations like, grease is overconsumed creating a threat to the concrete quality on the surface and we often see a concrete surface area where grease applied on formwork seen to be wet even after longer time of application and removal of same becomes a one more activity.

Normally the density of the grease shall be less than that of the water to ensure grease wont get mixed into the concrete. the grease ordered is almost a last product from the petroleum industry and to make more profits additives might be used by manufacturer to impart the colors and for increasing the density. this leads to reduction in the coverage, a good color of grease and the grease is not getting dried off quickly post de-shuttering of shutters.

It becomes important to check quality of the grease used for construction activity to ensure no cost overrun and there are no issues in doing further activities like application of plasters and paint on surface. as the grease is only serving the purpose of ease in release of shutter post concrete. we can verify the density of the grease by measuring its weight per unit volume.

This can also become a tedious task when the sample volume is smaller and the scope for error is more in correctly filling the container for calculations of density. sometimes it might be time consuming and proving the grease has higher density.

We can do a very quick and easy test by which we can recognize the quality of the grease. there is no rocket science or critical measurement or calculations are involved in it. simply take a small sample of grease and throw it in the water. a grease which has lower density will float on the water, a grease with additives added for increasing its weight and other properties will simply sink into the water showing the failure in required density.

A grease with lower density dries off quickly, covers a larger area of shutter and does not cause complications in further activities. also the removal of same from the surface is easier.

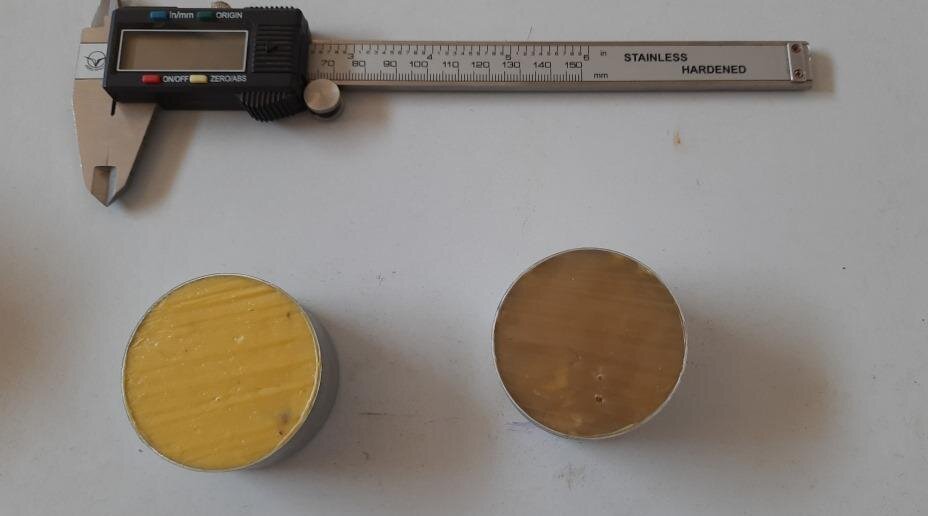

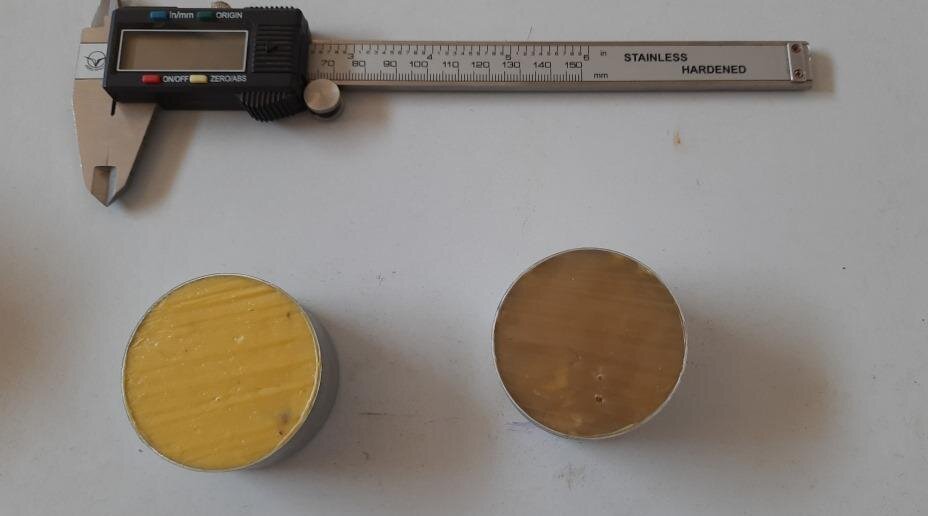

Below photograph shows two samples of grease tested for density by placing them into a water bucket, a sample which is floating in water showing lower density than the water and has good properties. a sample which sank to base is having higher density than the water and definitely had reverse properties of what stated for floating grease.

As the grease is not used for the important application in construction industry specially when it comes to using as a shutter release agent. mostly the quality checking of this material is neglected and vendors can modify its properties for their own benefits which may results into shabby final finish after some time when the applied grease on sub surface is not getting cleaned properly and due to timeline finishing is completed. to avoid issues in later stage, performing a density test for grease at the time of receipt is highly beneficial and this test wont require much time or knowledge of how to do test.

I hope this will help you in assuring best quality grease is used for shutter releasing in critical areas at your projects.

As the specifications are not provided along with the product name, this will lead to variety of grease supply, some with a good quality and some with bad quality in terms of its properties. Grease is supplied in Kg / MT and the applied surface coverage is calculated base on the volume.

During construction we might come across a situations like, grease is overconsumed creating a threat to the concrete quality on the surface and we often see a concrete surface area where grease applied on formwork seen to be wet even after longer time of application and removal of same becomes a one more activity.

Normally the density of the grease shall be less than that of the water to ensure grease wont get mixed into the concrete. the grease ordered is almost a last product from the petroleum industry and to make more profits additives might be used by manufacturer to impart the colors and for increasing the density. this leads to reduction in the coverage, a good color of grease and the grease is not getting dried off quickly post de-shuttering of shutters.

It becomes important to check quality of the grease used for construction activity to ensure no cost overrun and there are no issues in doing further activities like application of plasters and paint on surface. as the grease is only serving the purpose of ease in release of shutter post concrete. we can verify the density of the grease by measuring its weight per unit volume.

This can also become a tedious task when the sample volume is smaller and the scope for error is more in correctly filling the container for calculations of density. sometimes it might be time consuming and proving the grease has higher density.

We can do a very quick and easy test by which we can recognize the quality of the grease. there is no rocket science or critical measurement or calculations are involved in it. simply take a small sample of grease and throw it in the water. a grease which has lower density will float on the water, a grease with additives added for increasing its weight and other properties will simply sink into the water showing the failure in required density.

A grease with lower density dries off quickly, covers a larger area of shutter and does not cause complications in further activities. also the removal of same from the surface is easier.

Below photograph shows two samples of grease tested for density by placing them into a water bucket, a sample which is floating in water showing lower density than the water and has good properties. a sample which sank to base is having higher density than the water and definitely had reverse properties of what stated for floating grease.

As the grease is not used for the important application in construction industry specially when it comes to using as a shutter release agent. mostly the quality checking of this material is neglected and vendors can modify its properties for their own benefits which may results into shabby final finish after some time when the applied grease on sub surface is not getting cleaned properly and due to timeline finishing is completed. to avoid issues in later stage, performing a density test for grease at the time of receipt is highly beneficial and this test wont require much time or knowledge of how to do test.

I hope this will help you in assuring best quality grease is used for shutter releasing in critical areas at your projects.