Finite Element Analysis (FEA) is an essential tool used by engineers to simulate how a product will react to forces like heat, pressure, and vibration. It breaks down a complex design into small elements connected by nodes. This helps engineers see how a structure behaves before it’s built.

Finite Element Analysis (FEA) is an essential tool used by engineers to simulate how a product will react to forces like heat, pressure, and vibration. It breaks down a complex design into small elements connected by nodes. This helps engineers see how a structure behaves before it’s built.What FEA Does

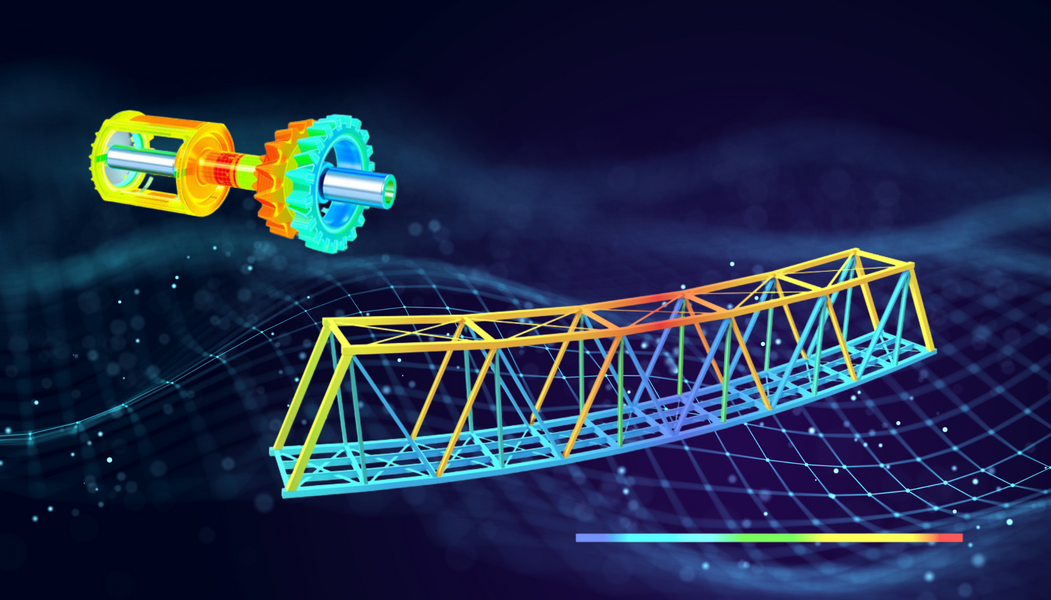

FEA helps identify stress, strain, and deformation in materials. It’s widely used in industries such as automotive, aerospace, civil, and biomedical engineering. Engineers use it to improve safety, performance, and efficiency while reducing costs.

How FEA Works

- Preprocessing – Create the digital model, define material properties, and mesh the model.

- Solution – Apply loads, heat, or other forces and define boundary conditions.

- Postprocessing – Analyze results using visual tools like stress maps to check for weak areas.

Why Accuracy Matters

Accuracy in FEA depends on the quality of the mesh, the correct definition of material properties, and the proper application of boundary conditions. Using the right type of elements (1D, 2D, or 3D) also affects results.

Why FEA is Valuable

FEA reduces the need for physical prototypes, speeds up development, cuts costs, and ensures safety. It’s a key part of modern engineering design.

For professional FEA training, visit PIGSO LEARNING and grow your engineering skills.