AIM: To find the grade of given bituminous material.

APPARATUS:

It consists of items like container, needle, water bath, penetrometer, stop watch etc.

PROCEDURE:

The bitumen is softened to a pouring consistency between 75 degree and 100 degree above the approximate temperature at which bitumen softens. The sample material is thoroughly stirred to make it homogenous and free from air bubbles and water. The sample material is then poured into the container to a depth at least 15 mm more than the expected penetration. The sample containers are cooled in atmosphere of temperature not lower than 13 degree for one hour. Then they are placed in temperature controlled water bath at a temperature of 25 degree for a period of one hour.

The sample container is placed in the transfer tray with water from the water bath and placed under the needle of the penetrometer. The weight of needle, shaft and additional weight are checked. The total weight of this assembly should be 100g. Using the adjusting screw, the needle assembly is lowered and the tip of the needle is made to just touch the top surface of the sample; the needle assembly is clamped in this position. The contact of the tip of the needle is checked using the mirror placed on the rear of the needle. The initial reading of the penetrometer dial is either adjusted to zero or the initial reading is taken before releasing the needle. The needle is released exactly for a period of 5.0 sec by pressing the knob and the final reading is taken on the dial. At lease three measurements are made on this sample by testing at distance of not less than 100 mm apart. After each test the needle is disengaged and cleaned with benzene and carefully dried. The sample container is also transferred in the water bath before next testing is done so as to maintain a constant temperature of 25 degree. The test is repeated with sample in the other containers.

Results

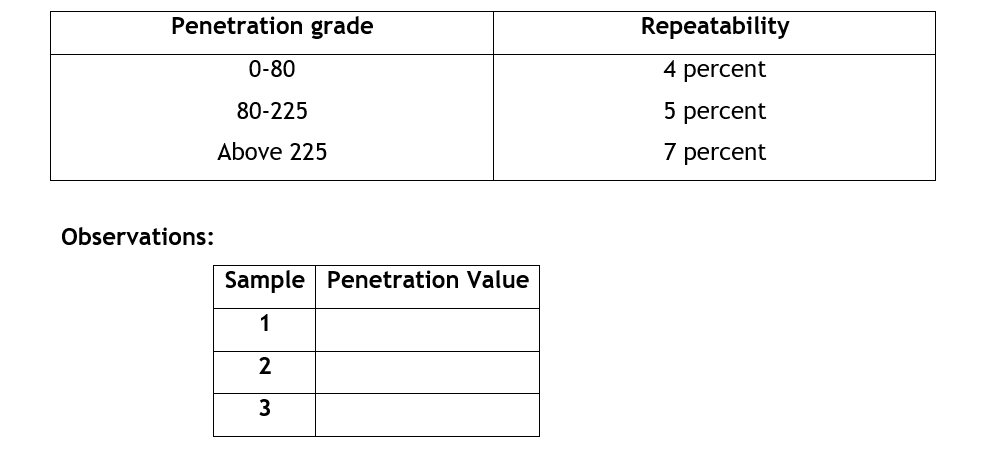

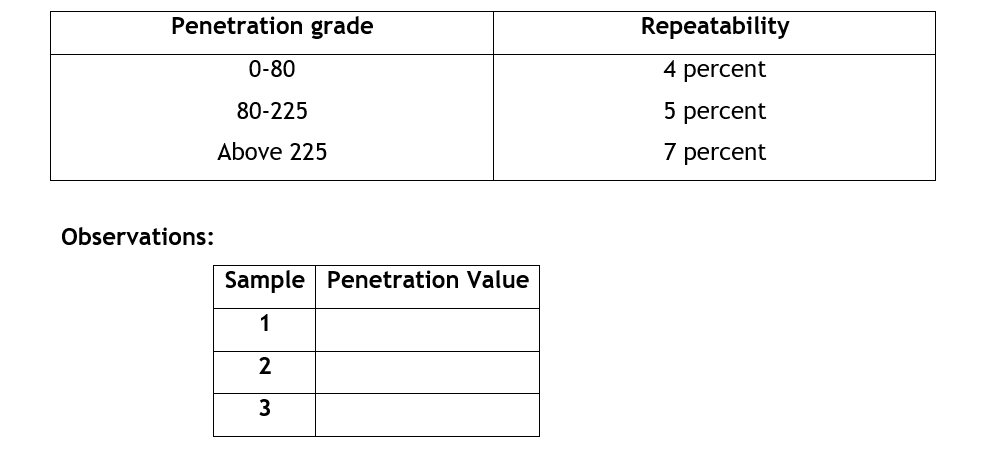

The difference between the initial and final penetration readings is taken as the penetration value. The mean value of three penetration measurements is reported as the penetration value. It is further specified by ISI that results of each measurement should not vary from the mean value reported below by more than the following:

APPLICATIONS OF PENETRATION TEST:

Penetration test is the most commonly adopted test on bitumen to grade the material in terms of its hardness. Depending up to the climatic condition and type of construction, bitumen of different penetration grades are used, 80/10 bitumen denotes that the penetration value ranges between 80 and 100. The penetration values of various types of bitumen used in pavement construction in this country range between 0 and 225. For bituminous macadam and penetration macadam Indian Roads Congress suggests bitumen grades 30/40, 60/70 and 80/100. In warmer regions lower penetration grades from preferred and in colder regions bitumen with higher penetration values are used.

The penetration test is not intended to estimate the consistency of softer materials like cutback or tar, which are usually graded by a viscosity test in an orifice viscometer.

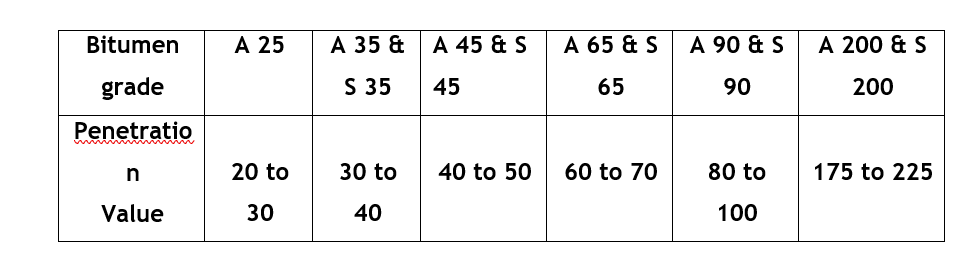

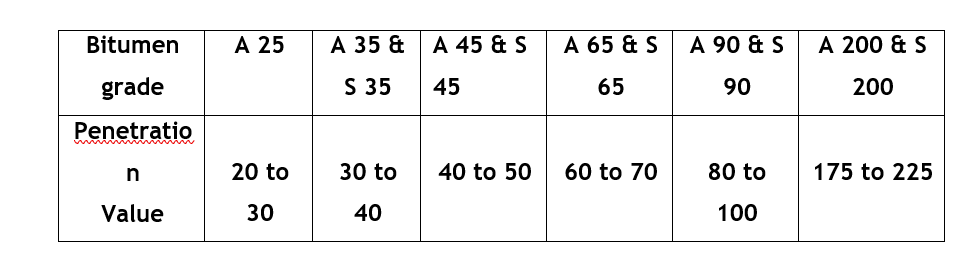

The India Standards Institution has classified paving bitumen available in this country into the following six categories depending on the penetration values. Grades designated 'A' (such as A 35) are from Assam Petroleum and those designated 'S' (such as S 35) are from other sources.

APPARATUS:

It consists of items like container, needle, water bath, penetrometer, stop watch etc.

PROCEDURE:

The bitumen is softened to a pouring consistency between 75 degree and 100 degree above the approximate temperature at which bitumen softens. The sample material is thoroughly stirred to make it homogenous and free from air bubbles and water. The sample material is then poured into the container to a depth at least 15 mm more than the expected penetration. The sample containers are cooled in atmosphere of temperature not lower than 13 degree for one hour. Then they are placed in temperature controlled water bath at a temperature of 25 degree for a period of one hour.

The sample container is placed in the transfer tray with water from the water bath and placed under the needle of the penetrometer. The weight of needle, shaft and additional weight are checked. The total weight of this assembly should be 100g. Using the adjusting screw, the needle assembly is lowered and the tip of the needle is made to just touch the top surface of the sample; the needle assembly is clamped in this position. The contact of the tip of the needle is checked using the mirror placed on the rear of the needle. The initial reading of the penetrometer dial is either adjusted to zero or the initial reading is taken before releasing the needle. The needle is released exactly for a period of 5.0 sec by pressing the knob and the final reading is taken on the dial. At lease three measurements are made on this sample by testing at distance of not less than 100 mm apart. After each test the needle is disengaged and cleaned with benzene and carefully dried. The sample container is also transferred in the water bath before next testing is done so as to maintain a constant temperature of 25 degree. The test is repeated with sample in the other containers.

Results

The difference between the initial and final penetration readings is taken as the penetration value. The mean value of three penetration measurements is reported as the penetration value. It is further specified by ISI that results of each measurement should not vary from the mean value reported below by more than the following:

APPLICATIONS OF PENETRATION TEST:

Penetration test is the most commonly adopted test on bitumen to grade the material in terms of its hardness. Depending up to the climatic condition and type of construction, bitumen of different penetration grades are used, 80/10 bitumen denotes that the penetration value ranges between 80 and 100. The penetration values of various types of bitumen used in pavement construction in this country range between 0 and 225. For bituminous macadam and penetration macadam Indian Roads Congress suggests bitumen grades 30/40, 60/70 and 80/100. In warmer regions lower penetration grades from preferred and in colder regions bitumen with higher penetration values are used.

The penetration test is not intended to estimate the consistency of softer materials like cutback or tar, which are usually graded by a viscosity test in an orifice viscometer.

The India Standards Institution has classified paving bitumen available in this country into the following six categories depending on the penetration values. Grades designated 'A' (such as A 35) are from Assam Petroleum and those designated 'S' (such as S 35) are from other sources.