How and why do this pile integrity test (PIT)......????

A pile integrity test is nothing but finding out if there are any issues in the pile which is cast in situ, as there is practically no chance to find the quality of the pile which is embedded in the earth.

In technical terms, Pile integrity test (PIT), or as

ASTM D5882 refers to it as "low strain impact integrity testing of deep foundation is a widely used nondestructive test method for the evaluation of pile quality, integrity and to help estimate the unknown length of existing piles and foundations.

Pile integrity test can be either used for forensic evaluations on existing piles or quality assurance in the new construction.

The integrity test is applicable to driven concrete piles and cast-in-place piles.

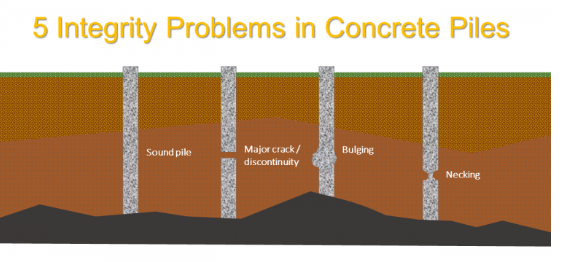

The following image provides a visual summary of major integrity issues in deep foundations.

A pile integrity test provides the following information:

- Continuity of the pile.

- Whether there are any defects like cracks etc

- Whether there is necking in the pile

- Whether there is any bulging in the pile

How the test is performed?

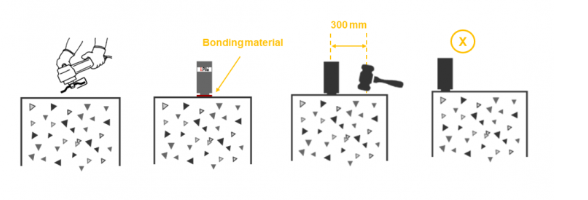

Surface preparation is the first thing to do when performing a pile integrity test. Remove top laitance etc with help of grinder so as to expose the sound concrete surface of the piles.

The acceleration sensor should be placed on concrete firmly. To do so, a couplant material should be used to attach the acceleration sensor the pile head. An impactor (usually a hand-held hammer) is used for

impacting pile head; the impact should be applied axially with the pile.

Motion transducer should be capable of detecting and recording the reflected echos over the pile top. Acceleration, velocity, or displacement transducers can be used for this purpose. At the minimum, acceleration transducer should have an Analog to Digital Converter with 12 bit resolution; and a Sample Frequency of at least 25 KHz.

The location of the sensor should be selected

away from the edges of the pile. The integrity testing should be performed no sooner than

7 days after casting or after concrete strength achieves at least 3/4 of its design strength, whichever occurs earlier.

The distance between the impact location and the sensor should be

no larger than 300 mm. Several impacts are applied to the top of the pile.

The reflected echos are then recorded for each individual impact.

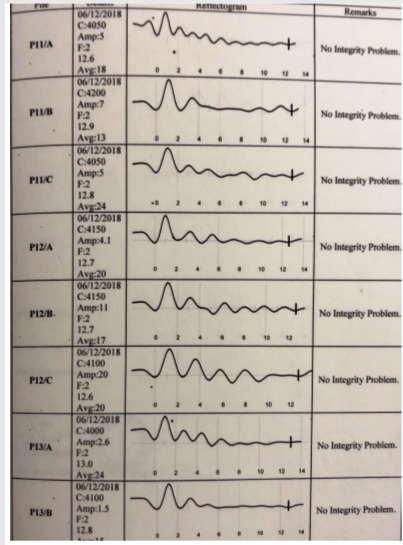

A typical reflectogram will look something shown below:

Please note that INTEGRITY TEST is to be conducted for each and every pile which are there for a particular structure and not a single pile can be skipped which kindly make note.

Hope that some basics of integrity test is clear to you.....

. Have conducted numerous tests on piles which were used for ESR in number of ESR built by us for our company in Mumbai.

Apart from the INTEGRITY TESTS you also need to conduct the DYNAMIC LOADING TEST which is basically to find out the load-bearing capacity of the piles. Dynamic loading test are conducted based on the requirements of the structural engineer.