WORKABILITY OF CONCRETE – VEE BEE TEST

AIM: To find workability of concrete by Vee-Bee consistency test in terms of Vee Bee Seconds

APPARATUS:

Vee Bee consistometer, Stopwatch, Balance, Tray, Tamping rod, measuring jar, Weights and Trowels.

THEORY:

The consistometer is used for determining the consistency of concrete by vibrating and transforming a concrete specimen from the shape of conical frustum into a cylinder.

DESCRIPTION:

The consistometer consists of a

AIM: To find workability of concrete by Vee-Bee consistency test in terms of Vee Bee Seconds

APPARATUS:

Vee Bee consistometer, Stopwatch, Balance, Tray, Tamping rod, measuring jar, Weights and Trowels.

THEORY:

The consistometer is used for determining the consistency of concrete by vibrating and transforming a concrete specimen from the shape of conical frustum into a cylinder.

DESCRIPTION:

The consistometer consists of a

- A vibrator table, which vibrates a rate of 3000 vibrations / min.

- A metal pot, which holds the specimen when the concrete is vibrated. It is secured to the vibrator table by bolts.

- Slump cone of 300 mm high, 200 mm at the bottom and 100 mm at the top (Open both ends).

- Swivel arm holder: A tube, which is fixed the rear of the base of the vibrator table. It has 4 positioning slots for swivel arm to position the metal cone over the slump cone or Perspex disc on the specimen or to position both of them away.

- Swivel arms the Swivel moves freely inside the swivel arm holder. A metal rod and a guide sleeve are fixed to the swivel arm. The graduated metal rod passes through the guide sleeve.

- Metal cone - this is in the form of a frustum of cone with open ends (funnel). This is fixed to the swivel arm

- Graduated rod

- Tamping rod. A metal rod of 16 mm x 60 cm. long with one end bullet ended.

- Position the metal cone over the slump cone. Place the concrete inside the slump cone in 4 layers each approximately 1/4 of the height. Strokes are applied by the rounded end of the tamping rod. Distribute the strokes in a uniform manner over the cross section.

- After the top layer has been rodded, position the metal cone of the swivel arm away, and strike off the concrete, level with the top of the cone using a trowel so that the mould is exactly filled.

- Remove any material spilled inside the metal pot or sticking on to the side of the slump filled.

- Position the Perspex disc over the cone and note down the reading on the graduated rod (L1). After keeping the disc away, lift the slump cone vertically and remove.

- Position the disc over the concrete. Note down the reading of the graduated rod (L2). The difference in the readings gives the slump in Centimeters.

- Switch on the vibrator starting a stopwatch simultaneously. Allow the

- The consistency of the concrete is expressed in Vee-Bee degrees which are

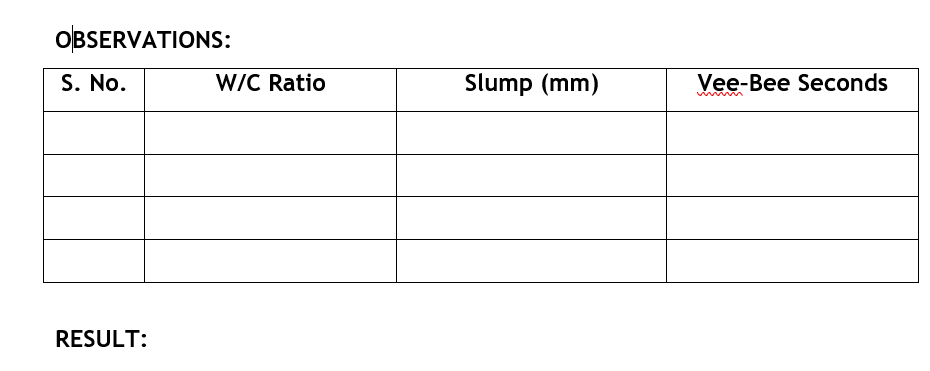

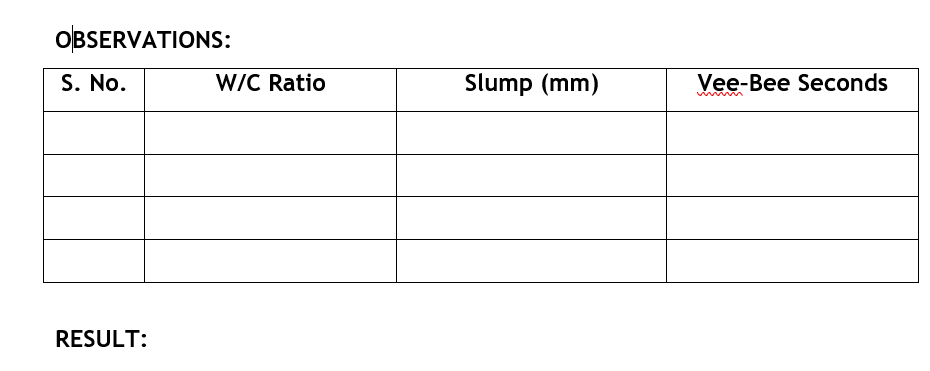

- Repeat the procedure of different W/C ratios viz.: 0.4, 0.5, 0.55, 0.6 & 0.65.

- Draw a graph between slump in centimeters and Vee – Bee Degrees.