As all might be aware about, cutting trees in India for making wooden furniture's and other construction materials is not allowed.

All wood comes from Singapore, Malaysia, South Africa etc.

The wood is classified into different names base on their properties like

its density, color etc.

known names in market

Red merandi, yellow merandi, burma teak, yellow btc, saal etc. and there are many names as per the species and property.

Wood comes to India through ships all the way from sea to Kolkata and Gujrat (some wood is transported to Bhiwandi too and may be at some other places in India)

These wood logs have there own properties caused by nature like cracks, splits and hollow cores etc.

Wood is kept at stack yard as it is unless there is order for it, this ensure the natural seasoning of wood (some seasoning also happens during transport through ships)

Wood logs are first cut into small sizes blocks on huge cutters.

Then as per the order wood blocks then cut to the sizes as per order (Raw cut size is more than actual requirement size as wood tends to shrink and my get less dimension during finish cutting for purpose)

Calculation on what sizes to be cut at what level are decided by manufacturer considering the wastage and other parameters (rates are quoted accordingly)

Cut wood then stacked nearby.

some may prefer to do air seasoning of wood which is cut without order or if they want.

The Cut wood is then supplied to customers as per their needs i.e. - with or without seasoning.

When customer choose to get season wood then that is sent for further processing

at seasoning chambers.

Seasoning is process in which water from the wood is extracted by means of increasing surrounding temperatures which cause water to get escape out from it.

Seasoning chambers have the basic function listed below.

Heating coil to increase the temperatures.

Fans to keep air circulated inside the chambers.

Exhaust cutout at top to maintain the atmospheric pressure.

Temperature gauge outside the chamber to control the temperature and indicate the temperature.

Seasoning is done to a level which can keep wood in its shape and do not allow it to develop the cracks due to escaping moisture from it.

Seasoning parameters are different for different type of woods.

Over seasoning can cause

Bending in profile of wood

Thorough cracking in wood which makes it unusable.

Though some cracking happens on wood surface during this process and some of the wood close to the heater may get thorough cracks on it (Ordered quantity must be define considering this effect if you are ordering season wood )

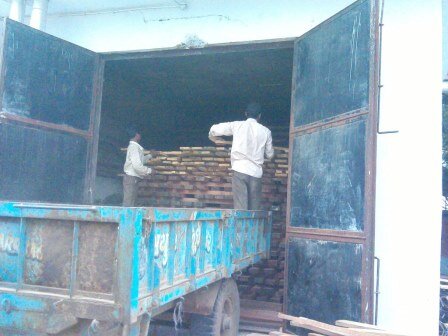

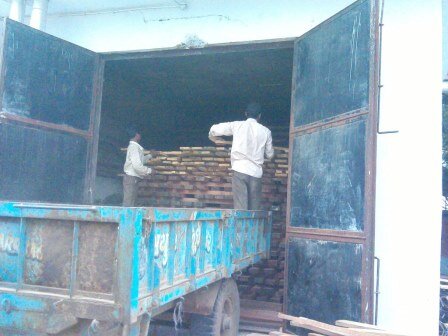

After seasoning wood is transported to customer in tractor, tempo, trailer as per the size of order and location of transport.

Do ensure the correctly seasoning of wood, by checking its moisture level with moisture meter.

Sometime a moisture meter used by seasoning agency may be faulty, better take your own moisture meter to test the wood moisture.

If you are ordering the wood during monsoon, ensure it is covered during transport to avoid gaining of moisture due to rain water (Specially if its seasoned).

Woods have inheritable properties such as

cracks

Knots

Location of knot plays important role, ensure you have good team of carpenter who knows how to cut into frames and where we can make that knot goes.

Having a knot at edges will make damages to frame sooner and customers will get dissatisfied.

Once the cut wood or season wood reaches your place, then you can cut it further to make what ever you want as per your specifications.

This is the process of wooden frame manufacturing.

Same way the packing material is made for containers using a cheapest wood i.e. pine frames.

If you want to appreciate me, you can do that by clicking on like or posting your comments on it by replying here

Do not copy and paste my post somewhere else without my consent.

All wood comes from Singapore, Malaysia, South Africa etc.

The wood is classified into different names base on their properties like

its density, color etc.

known names in market

Red merandi, yellow merandi, burma teak, yellow btc, saal etc. and there are many names as per the species and property.

Wood comes to India through ships all the way from sea to Kolkata and Gujrat (some wood is transported to Bhiwandi too and may be at some other places in India)

These wood logs have there own properties caused by nature like cracks, splits and hollow cores etc.

Wood is kept at stack yard as it is unless there is order for it, this ensure the natural seasoning of wood (some seasoning also happens during transport through ships)

Wood logs are first cut into small sizes blocks on huge cutters.

Then as per the order wood blocks then cut to the sizes as per order (Raw cut size is more than actual requirement size as wood tends to shrink and my get less dimension during finish cutting for purpose)

Calculation on what sizes to be cut at what level are decided by manufacturer considering the wastage and other parameters (rates are quoted accordingly)

Cut wood then stacked nearby.

some may prefer to do air seasoning of wood which is cut without order or if they want.

The Cut wood is then supplied to customers as per their needs i.e. - with or without seasoning.

When customer choose to get season wood then that is sent for further processing

at seasoning chambers.

Seasoning is process in which water from the wood is extracted by means of increasing surrounding temperatures which cause water to get escape out from it.

Seasoning chambers have the basic function listed below.

Heating coil to increase the temperatures.

Fans to keep air circulated inside the chambers.

Exhaust cutout at top to maintain the atmospheric pressure.

Temperature gauge outside the chamber to control the temperature and indicate the temperature.

Seasoning is done to a level which can keep wood in its shape and do not allow it to develop the cracks due to escaping moisture from it.

Seasoning parameters are different for different type of woods.

Over seasoning can cause

Bending in profile of wood

Thorough cracking in wood which makes it unusable.

Though some cracking happens on wood surface during this process and some of the wood close to the heater may get thorough cracks on it (Ordered quantity must be define considering this effect if you are ordering season wood )

After seasoning wood is transported to customer in tractor, tempo, trailer as per the size of order and location of transport.

Do ensure the correctly seasoning of wood, by checking its moisture level with moisture meter.

Sometime a moisture meter used by seasoning agency may be faulty, better take your own moisture meter to test the wood moisture.

If you are ordering the wood during monsoon, ensure it is covered during transport to avoid gaining of moisture due to rain water (Specially if its seasoned).

Woods have inheritable properties such as

cracks

Knots

Location of knot plays important role, ensure you have good team of carpenter who knows how to cut into frames and where we can make that knot goes.

Having a knot at edges will make damages to frame sooner and customers will get dissatisfied.

Once the cut wood or season wood reaches your place, then you can cut it further to make what ever you want as per your specifications.

This is the process of wooden frame manufacturing.

Same way the packing material is made for containers using a cheapest wood i.e. pine frames.

If you want to appreciate me, you can do that by clicking on like or posting your comments on it by replying here

Do not copy and paste my post somewhere else without my consent.