Site Engineer should check this in Reinforcement Steel work

Engineers who are working at construction project and actually look after the construction activities going at project, should check the following points during Reinforcement steel works.

Before starting reinforcement work formwork should be cleaned and oiled. Once reinforcement work started do not allow anyone to carry shuttering oil in that area.

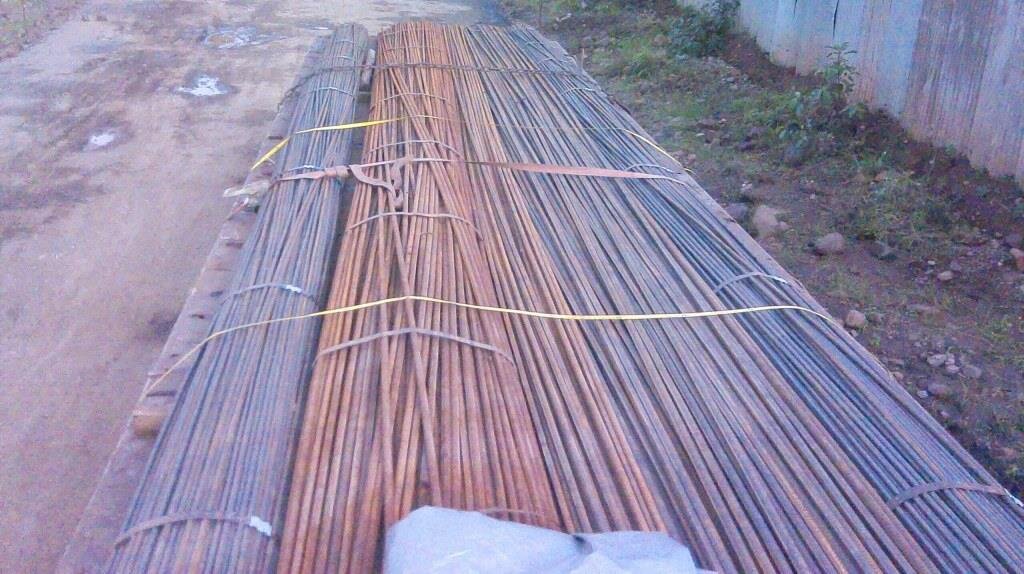

Reinforcement steel should be free from oil, mud etc.

Before fixing the reinforcement, it should be checked for required lap length.

Lapping of column should not be allowed in beam column junctions.

Sharp joggle should not be done, in unavoidable condition it can be joggle by 1” in 2’.

Cover block should be checked for its correct size before fixing.

Lapping of the bars should be done in staggered way, not more than 50% bars should be lap at same level.

Reduction of column reinforcement and size should be done in beam area as per structural details.

In beam column junctions, after fixing of beam reinforcement, column stirrups should be fixed as per spacing in place.

Ring hooks should be bent at 135o.

Binding wire ends should be bent inside column.

In case of external face beams, the reinforcement on the external face should pass from the inside of the column reinforcement.

Steel chairs, used in slab reinforcement, should be tied such that each leg is resting on 2 bars of the slab reinforcement, so that they don’t topple over, while concreting.

If oiled spilled over reinforcement bar, it should be clean with detergent before concreting.

Reinforcement should not be left below the casted floor it should be immediately shifted to the working floor.

Engineers who are working at construction project and actually look after the construction activities going at project, should check the following points during Reinforcement steel works.

Before starting reinforcement work formwork should be cleaned and oiled. Once reinforcement work started do not allow anyone to carry shuttering oil in that area.

Reinforcement steel should be free from oil, mud etc.

Before fixing the reinforcement, it should be checked for required lap length.

Lapping of column should not be allowed in beam column junctions.

Sharp joggle should not be done, in unavoidable condition it can be joggle by 1” in 2’.

Cover block should be checked for its correct size before fixing.

Lapping of the bars should be done in staggered way, not more than 50% bars should be lap at same level.

Reduction of column reinforcement and size should be done in beam area as per structural details.

In beam column junctions, after fixing of beam reinforcement, column stirrups should be fixed as per spacing in place.

Ring hooks should be bent at 135o.

Binding wire ends should be bent inside column.

In case of external face beams, the reinforcement on the external face should pass from the inside of the column reinforcement.

Steel chairs, used in slab reinforcement, should be tied such that each leg is resting on 2 bars of the slab reinforcement, so that they don’t topple over, while concreting.

If oiled spilled over reinforcement bar, it should be clean with detergent before concreting.

Reinforcement should not be left below the casted floor it should be immediately shifted to the working floor.