Soundness Test for Cement

Ref : IS 4031 (part III)

Purpose : To determine the soundness of Ordinary Portland Cement

Significance : It is essential that the cement paste, once it has set, does not undergo large changes in volume i.e. - there should not be appreciable expansion, which under conditions of restraint could result in disruption of hardened cement paste. By soundness test this property of volume change can be checked.

Apparatus:

Weighing balance & weights

Le – Chatelier moulds

Vicat apparatus

Plunger

Trowels, tray and time watch

Water bath

Glass sheets and oil

Test Procedure:

Take 400gm of cement and find its standard consistency

Place the lightly oiled Le – Chatelier mould on a lightly oiled glass sheet

Prepare a cement paste formed by gauging cement with 0.78 times the water required to give a paste of standard consistency

Fill the Le – Chatelier mould with this cement paste made in step 3 of procedure

Cover the mould with another piece of lightly oiled glass sheet

Place a small weight on this covering glass sheet and immediately submerge the whole assembly in water at a temperature of 27 ± 2oC and keep it there for 24 hours

Measure the distance between the indicators to the nearest 0.5mm. Submerge the mould again in water at a temperature of 27 ± 2oC

Bring the water to boiling temperature in 25 to 30 minutes and keep it boiling for 3 hours

Remove the mould from water, allow it to cool and measure the distance between the indicators. The difference between these two measurements, ie in step (7) & step (9) of procedure indicates the expansion of cement

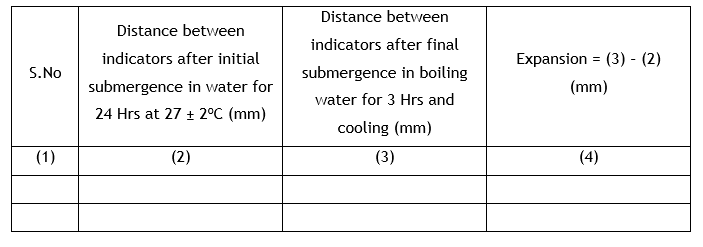

Observation Table:

Limit : Maximum expansion 10mmFrequency : For every batch received

Note: (as per the same IS) In the event of cement failing to meet the test for soundness, a retest may be made after aeration. For this purpose, spread out the cement in a layer of 75mm thickness and store it for 7 days in an atmosphere maintained at 27 ± 2oC and relative humidity of 50 to 80%. Retest this cement as per the above procedure.