What is a Slab?

Slabs are constructed to provide flat surfaces, usually horizontal, in building floors, roofs, bridges, and other types of structures. The slab may be supported by walls, by reinforced concrete beams usually cast monolithically with the slab, by structural steel beams, by columns, or by the ground. Slabs are classified into 16 types.

Types of slabs in construction:-

There are 16 different types of Slabs in Construction. Some of them are outdated and some of them are frequently used everywhere. In this article i ll give a detailed explanation about an each slab where to use particular slab.

Since this is a lengthy article, we have created a table of contents below for easy navigation.

1.FLAT SLAB:-

Flat slab is a reinforced concrete slab supported directly by concrete columns or caps. Flat slab dont have beams. They are supported on columns itself. Loads are directly transferred to columns. In this type of construction a plain ceiling is obtained thus giving attractive appearance from architectural point of view. The plain ceiling diffuses the light better and is considered less vulnerable in the case of fire than the usual beam slab construction.The flat slab is easier to construct and requires less formwork. The thickness of

Flat slab is minimum 8″ or 0.2m.

THERE ARE FOUR DIFFERENT TYPES OF FLAT SLABS:-

Pic credits: Slideshare

2. CONVENTIONAL SLAB:-

The slab which is supported with Beams and columns is called conventional slab. In this kind of slab the thickness of slab is small whereas depth of beam is large and load is transferred to beams and from beams to columns. It requires more formwork when compared with the flat slab. and there is no need of providing column caps in conventional slab. The thickness of conventional slab is 4″ or 10cm. 5″ to 6″ inches is recommended if the concrete will receive occasional heavy loads, such as motor homes or garbage trucks. Normally it is square in shape and has a length of 4m. Reinforcement is provided in conventional slab and the bars which are set in horizontal are called Main Reinforcement Bars and bars which are set in vertical are called Distribution bars. hese types of slabs are used in constructing floors of multi storeyed building.

Based on length and breadth of Conventional Slab is classified into two types:

One way slab is a slab which is supported by beams on the two opposite sides to carry the load along one direction.The ratio of longer span (l) to shorter span (b) is equal or greater than 2, considered as One way slab because this slab will bend in one direction i.e in the direction along its shorter span.However minimum reinforcement known as distribution steel is provided along the longer span above the main reinforcement to distribute the load uniformly and to resist temperature and dhrinkage stresses.

In general length of slab is 4m. But in one way slab one side length is 4m and other side length is more than 4m. So it satisfies the above equation. In one way slab main reinforcement is provided in shorter span and distribution reinforcement is provided in longer span. Distribution bars are cranked to resist the formation of stresses.

Example: Generally all the Cantilever slabs are one Way slab. Chajjas and verandahs are an practical example of one way slab.

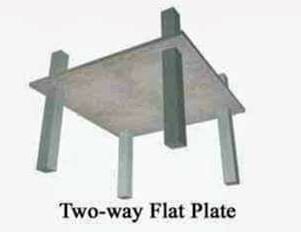

2. TWO WAY SLAB:

Two way slab is a slab supported by beams on all the four sides and the loads are carried by the supports along both directions, it is known as two way slab. In two way slab, the ratio of longer span (l) to shorter span (b) is less than 2.The slabs are likely to bend along the two spans in this load is transferred in both the directions to the four supporting edges and hence distribution reinforcement is provided in both the directions.

In this kind of slab the length and breadth of slab is more than 4m. So distribution bars are provided at both the ends in two way slab. To resist the formation of stresses.

These types of slabs are used in constructing floors of multi storeyed building.

3. HOLLOW CORE RIBBED SLAB:-

Hollowcore ribbed slabs derive their name from the voids or cores which run through the units. The cores can function as service ducts and significantly reduce the self-weight of the slabs, maximising structural efficiency. The cores also have a benefit in sustainability terms in reducing the volume of material used. Units are generally available in standard 1200 mm widths and in depths from 110mm to 400 mm. There is total freedom in length of units. This kind of slab is used where the construction has to be done fast. These kind of slabs are Pre cast slabs which are readymade. The hollowcore ribbed slabs have between four and six longitudinal cores running through them, the primary purpose of the cores being to decrease the weight, and material within the floor, yet maintain maximal strength. To further increase the strength, the slabs are reinforced with 12mm diameter steel strand, running longitudinally.

By using tower cranes Hollow slabs are inserted between the beams. The gaps between the slab is filled with screed.

Screed is a concrete material generally we use 20mm aggrgegate in concrete whereas in screed we use baby chips(small broken stones) as aggregates.

Hollow core ribbed slabs have excellent span capabilities, achieving a capacity of 2.5 kN/m2 over a 16m span. The long-span capability is ideal for offices, retail or car park developments. Units are installed with or without a structural screed, depending on requirements. Slabs arrive on-site with a smooth pre-finished soffit. In car parks and other open structures, pre-finished soffits offer a maintenance free solution.

Slabs are constructed to provide flat surfaces, usually horizontal, in building floors, roofs, bridges, and other types of structures. The slab may be supported by walls, by reinforced concrete beams usually cast monolithically with the slab, by structural steel beams, by columns, or by the ground. Slabs are classified into 16 types.

Types of slabs in construction:-

There are 16 different types of Slabs in Construction. Some of them are outdated and some of them are frequently used everywhere. In this article i ll give a detailed explanation about an each slab where to use particular slab.

Since this is a lengthy article, we have created a table of contents below for easy navigation.

1.FLAT SLAB:-

Flat slab is a reinforced concrete slab supported directly by concrete columns or caps. Flat slab dont have beams. They are supported on columns itself. Loads are directly transferred to columns. In this type of construction a plain ceiling is obtained thus giving attractive appearance from architectural point of view. The plain ceiling diffuses the light better and is considered less vulnerable in the case of fire than the usual beam slab construction.The flat slab is easier to construct and requires less formwork. The thickness of

Flat slab is minimum 8″ or 0.2m.

THERE ARE FOUR DIFFERENT TYPES OF FLAT SLABS:-

- Slab without drop and column without column head(capital).

- Slab with drop and column without column head.

- Slab without drop and column with column head.

- Slab with drop and column with column head.

Pic credits: Slideshare

2. CONVENTIONAL SLAB:-

The slab which is supported with Beams and columns is called conventional slab. In this kind of slab the thickness of slab is small whereas depth of beam is large and load is transferred to beams and from beams to columns. It requires more formwork when compared with the flat slab. and there is no need of providing column caps in conventional slab. The thickness of conventional slab is 4″ or 10cm. 5″ to 6″ inches is recommended if the concrete will receive occasional heavy loads, such as motor homes or garbage trucks. Normally it is square in shape and has a length of 4m. Reinforcement is provided in conventional slab and the bars which are set in horizontal are called Main Reinforcement Bars and bars which are set in vertical are called Distribution bars. hese types of slabs are used in constructing floors of multi storeyed building.

Based on length and breadth of Conventional Slab is classified into two types:

- One-Way Slab

- Two-Way Slab

One way slab is a slab which is supported by beams on the two opposite sides to carry the load along one direction.The ratio of longer span (l) to shorter span (b) is equal or greater than 2, considered as One way slab because this slab will bend in one direction i.e in the direction along its shorter span.However minimum reinforcement known as distribution steel is provided along the longer span above the main reinforcement to distribute the load uniformly and to resist temperature and dhrinkage stresses.

In general length of slab is 4m. But in one way slab one side length is 4m and other side length is more than 4m. So it satisfies the above equation. In one way slab main reinforcement is provided in shorter span and distribution reinforcement is provided in longer span. Distribution bars are cranked to resist the formation of stresses.

Example: Generally all the Cantilever slabs are one Way slab. Chajjas and verandahs are an practical example of one way slab.

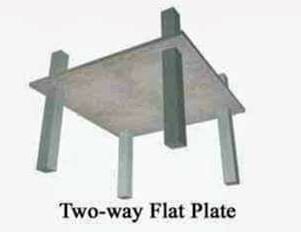

2. TWO WAY SLAB:

Two way slab is a slab supported by beams on all the four sides and the loads are carried by the supports along both directions, it is known as two way slab. In two way slab, the ratio of longer span (l) to shorter span (b) is less than 2.The slabs are likely to bend along the two spans in this load is transferred in both the directions to the four supporting edges and hence distribution reinforcement is provided in both the directions.

In this kind of slab the length and breadth of slab is more than 4m. So distribution bars are provided at both the ends in two way slab. To resist the formation of stresses.

These types of slabs are used in constructing floors of multi storeyed building.

3. HOLLOW CORE RIBBED SLAB:-

Hollowcore ribbed slabs derive their name from the voids or cores which run through the units. The cores can function as service ducts and significantly reduce the self-weight of the slabs, maximising structural efficiency. The cores also have a benefit in sustainability terms in reducing the volume of material used. Units are generally available in standard 1200 mm widths and in depths from 110mm to 400 mm. There is total freedom in length of units. This kind of slab is used where the construction has to be done fast. These kind of slabs are Pre cast slabs which are readymade. The hollowcore ribbed slabs have between four and six longitudinal cores running through them, the primary purpose of the cores being to decrease the weight, and material within the floor, yet maintain maximal strength. To further increase the strength, the slabs are reinforced with 12mm diameter steel strand, running longitudinally.

By using tower cranes Hollow slabs are inserted between the beams. The gaps between the slab is filled with screed.

Screed is a concrete material generally we use 20mm aggrgegate in concrete whereas in screed we use baby chips(small broken stones) as aggregates.

Hollow core ribbed slabs have excellent span capabilities, achieving a capacity of 2.5 kN/m2 over a 16m span. The long-span capability is ideal for offices, retail or car park developments. Units are installed with or without a structural screed, depending on requirements. Slabs arrive on-site with a smooth pre-finished soffit. In car parks and other open structures, pre-finished soffits offer a maintenance free solution.