In civil and geotechnical engineering, the stability of any structure starts with understanding the strength and behavior of the soil beneath. The Plate Load Test is one of the most trusted field methods to evaluate this behavior. It directly measures how much load the soil can bear and how it settles under pressure-two vital factors that determine the safety and longevity of any foundation.

It basically involves the application of incremental loading on a steel plate placed at foundation level and recording the corresponding settlements.

Here's a simplified overview of how it's done:

qₛ then obtained by multiplying the Safe Bearing Capacity obtained by a Factor of Safety, which is generally in between 2.5 and 3.

Safe Bearing Capacity (qₛ) = Factor of Safety (F) * Ultimate Bearing Capacity (qᵤ)

In the case of pavement design, the value of k, the Modulus of Subgrade Reaction, is also determined from the test results and aids in analyzing slab and pavement behavior under traffic loads.

The Plate Load Test is one of the most dependable tools in geotechnical engineering for assessing bearing capacity and settlement. It provides real-world data that helps engineers design safe, economical, and durable foundations.

By understanding how the soil reacts to applied pressure, engineers can ensure that every structure — from a small building to a massive bridge — stands on solid and reliable ground.

Image Source : www.aimil.com

Understanding Plate Load Test in Geotechnical Engineering

The Plate Load Test is a field-based experiment conducted for ascertaining the bearing capacity and settlement characteristics of soil at a site.It basically involves the application of incremental loading on a steel plate placed at foundation level and recording the corresponding settlements.

Important Results of plate load test that will help engineers decide:

- The safe bearing capacity of the soil.

- Expected settlement under structural loads.

- Modulus of subgrade reaction (k-value), as used in pavement design

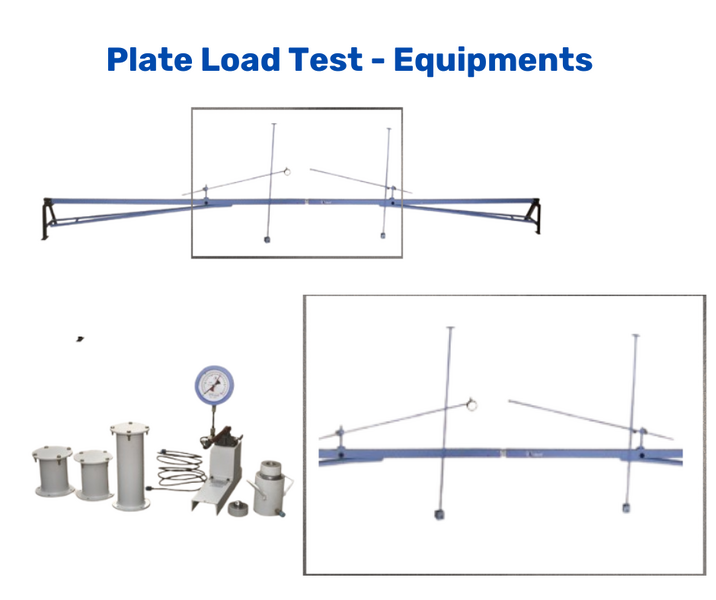

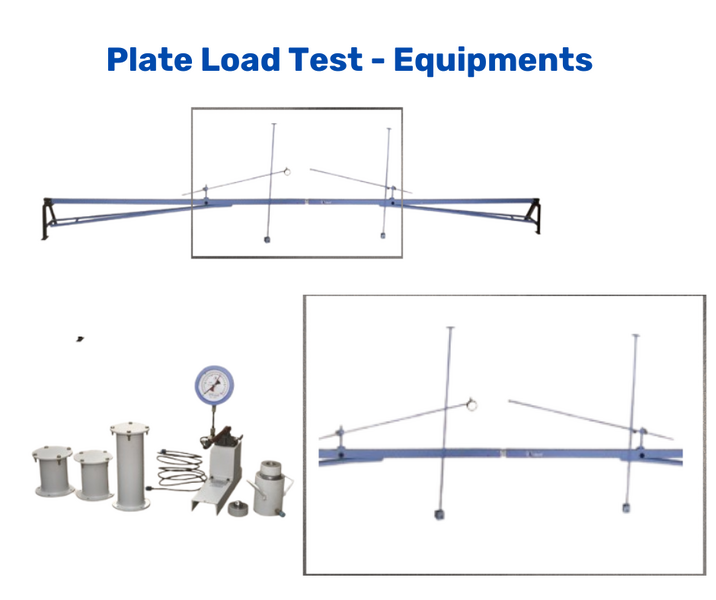

Equipment Used in Plate Load Test

- Mild Steel Plate: 300 mm to 750 mm diameter, usually circular and 25 mm thick.

- Hydraulic Jack: for applying the load on the plate.

- Reaction Frame or Load Platform: Normally a truck or heavy beam to provide counterweight.

- Dial Gauges: Settlement of the plate at every load increment is measured.

- Pressure Gauge: For the measurement of applied load pressure.

Plate Load Test Test Procedure (Step-by-Step)

The Plate Load Test is conducted according to IS: 1888 – 1982 (Method of Load Test on Soils).Here's a simplified overview of how it's done:

- Pit preparation: A pit is dug out where the foundation is intended. The bottom is smoothened and cleaned.

- Place the Steel Plate: The plate is placed centrally on the leveled surface. In case the ground is uneven, a thin layer of fine sand is spread underneath for full contact.

- Loading Arrangement: A hydraulic jack is positioned between the plate and a reaction system (such as a truck, beam or loaded platform).

- Apply Load in Increments: The load is applied in small increments, usually 1/5th of the expected ultimate load. After each increment of load, settlement is recorded by dial gauges at regular time intervals until the rate of settlement becomes negligible.

- Increase Load Till Failure or Limit: Loading is continued until a distinct failure (a sudden decrease in settlement) is achieved, or until the applied pressure reaches 1.5 times the proposed design load.

- Plot Load-Settlement Curve: The test results are plotted as a graph between pressure and settlement. From this curve, engineers determine the ultimate bearing capacity and safe bearing capacity of the soil.

Calculation and Interpretation

Ultimate Bearing Capacity (qᵤ) refers to the maximum pressure that soil can bear without causing failure.qₛ then obtained by multiplying the Safe Bearing Capacity obtained by a Factor of Safety, which is generally in between 2.5 and 3.

Safe Bearing Capacity (qₛ) = Factor of Safety (F) * Ultimate Bearing Capacity (qᵤ)

In the case of pavement design, the value of k, the Modulus of Subgrade Reaction, is also determined from the test results and aids in analyzing slab and pavement behavior under traffic loads.

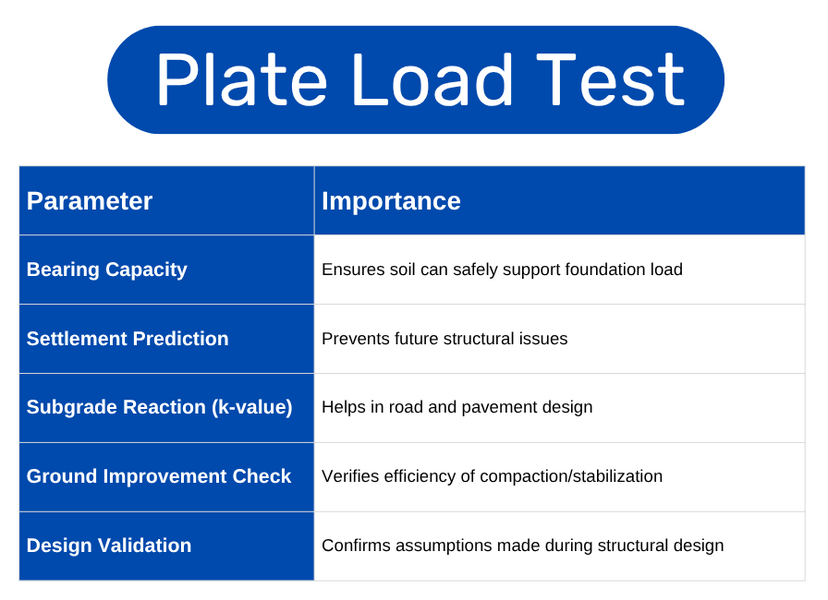

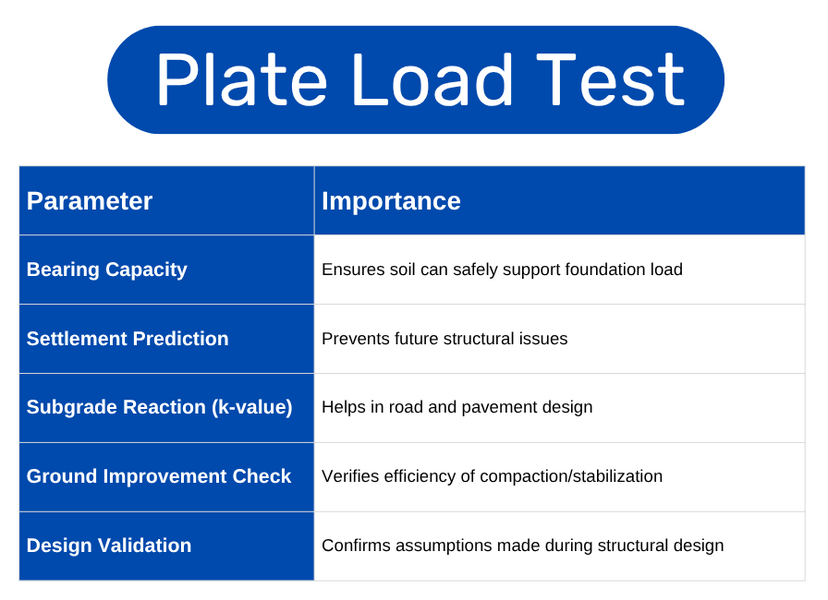

Importance of Plate Load Test in Geotechnical Engineering

- Determines Safe Bearing Capacity : This helps in choosing the correct type and size of foundation to ensure structural safety.

- Predicts Settlement Behaviour : It provides the correct data on how much the foundation will settle over time under an applied load.

- Validates Design Assumptions : It confirms the actual site soil conditions against theoretical design data.

- Ground Improvement Assessment : It serves to check the improvement in load-bearing performance after soil stabilization or compaction.

- Fundamental to Pavement Design : Determines the k-value-modulus of subgrade reaction, important in rigid pavement and runway design.

- Provides Real Field Data : Unlike lab tests, PLT directly reflects in-situ soil performance and gives a realistic picture of how the ground behaves under load.

Limitations of the Plate Load Test

Although the Plate Load Test is reliable, it has some limitations:- It represents a small area and may not be representative for large foundation behavior.

- It is time-consuming and requires heavy equipment setup.

- Plate Load Test is Less suitable for rocky or very soft soils.

- It cannot simulate long-term settlement because the test duration is too short.

Applications of Plate Load Test

- Building Foundations: Calculates safe load for shallow foundations

- Bridge & Tower Foundations: Provides stability under concentrated loads

- Roads & Pavements: Used for computation of subgrade reaction modulus

- Soil Improvement Projects: Verifies performance after compaction/stabilization.

- Embankment and Runway Construction: Checks settlement and bearing capacity of compacted layers.

Standard Reference for Plate Load Test

- IS 1888:1982 – Method of Load Test on Soils (Bureau of Indian Standards)

- IRC 58:2015 – Design of Plain Jointed Rigid Pavements for Highways

The Plate Load Test is one of the most dependable tools in geotechnical engineering for assessing bearing capacity and settlement. It provides real-world data that helps engineers design safe, economical, and durable foundations.

By understanding how the soil reacts to applied pressure, engineers can ensure that every structure — from a small building to a massive bridge — stands on solid and reliable ground.

Image Source : www.aimil.com