Determination of Liquid and Plastic limits

Ref : IS 2720 (part V)Purpose : To find plasticity index of soil.

Significant : Liquid limit and plasticity indexes are two important properties for the identification

and classification of fine grained soil.

Definitions :

- Liquid limit may be defined as the minimum water content at which the soil will flow under the application of very small shearing force.

- Plastic limit may be defined as the minimum moisture content at which the soil remains in a plastic state.

- Plasticity index is defined as the numerical difference between liquid and plastic limit.

- Plasticity is a property for clayey soils which may be explained as the ability to undergo changes in shape without rupture.

- Standard liquid limit device

- Standard grooving tools

- Spatula

- Evaporating dish

- Moisture containers

- Balance

- Oven

- Grounded glass plate.

Take 120g of dry pulverized soil sample passing 425μ IS sieve.

Mix thoroughly with distilled water in the evaporating dish to form a uniform thick paste.

Adjust the liquid limit device to have a free fall of cup through 10mm

Place a portion of the paste in the cap above the lowest spot and squeeze down with the spatula to have a horizontal surface.

The specimen is to be trimmed by firm strokes of spatula in such a way that the maximum depth of soil sample in the cup is 10mm.

Divide the soil in the cup along the diameter through the centre line of the can.

Give frim strokes of the grooving tool so as to get a clean sharp groove.

Rotate the crank at the rate of two revolutions per second so that the cup is lifted and dropped.

Continue the operation till the two halves of soil cake come into contact at the bottom of the groove along a distance of about 10mm

Record the number of blows

Dry the container in the oven for 24 hrs and determine the dry weight of the next day.

Calculate the moisture content of the soil.

Repeat the operation for at least three more times with slightly increased moisture contents each time and note down the blows so that there are at least four uniformly distributed readings in number of blows between 10 and 40 blows.

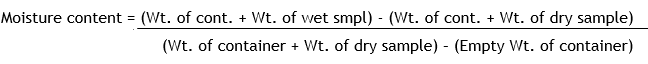

Calculations:

Flow curve is to be plotted by taking the no of blows in the log scale on the x – axis and moisture content in arithmetic scale on the y – axis.

Moisture content corresponding to 25 blows is to be noted down from the flow curve and round it off to nearest whole number that is the liquid limit of the soil.

Procedure for Plastic limit:

- Take 20 gms of dry pulverized soil passing through 425μ sieve.

- Mix the soil thoroughly with distilled water in evaporating dish till the soil paste is plastic enough to be easily moulded with fingers.

- Form a small ball with the fingers and roll it between fingers and the ground glass plate to thread.

- The rate of rolling should be between 80 and 90 strokes per minute (count a stroke as one complete motion of hand forward and back to the starting position).

- Continue the rolling till the diameter of the thread is 3mm.

- Now the soil is kneaded together to a hall and rolled again to form thread.

- This process of alternate rolling and threading is continued until the thread crumble under pressure required for rolling and the soil can no longer be rolled into a thread.

- If the crumbling starts at a diameter less than 3mm, the moisture content is more than plastic limit.

- If the crumbling starts at a diameter greater than 3mm, the moisture content is less than plastic limit.

- Obtain the thread which starts crushing at 3mm diameter under normal rolling.

- Place that thread in the moisture container immediately lid placed and find its weight.

- Keep the container in the oven for 24 hours.

- Find the dry weight of the soil along with container.

- The above procedure is repeated to get at least three consistent values of the plastic limit.

Calculation:

Plasticity index (Ip) = Liquid limit – Plastic limit (Ip = Wl – Wp)

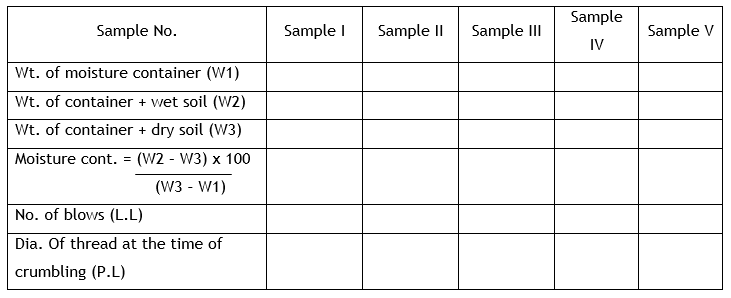

Observation Table:

Limits:

Liquid limit < 25%

Plastic limit < 6%

Frequency: One test for every 1500 M3 of borrowed material.