You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Need usefull method for getting low cracks

- Thread starter AZIMUL biswas

- Start date

RAJJOGISRI

Senior Member

Dnyan Deshmukh

Staff member

Over vibration can cause the fine materials to get accumulate at surface and near to form face.

If overvibrated, fines on surface will going to call for shrinkage.

As from picture and shape it look like max structure area have form finish, overvibration cant be seen.

Increase the pouring rate and keep control on vibration.

Airation - admixture used in concrete generally release air in concrete, the more effect of airation seen in self compacting concretes or super fluid concretes. This is non controllable, or u can control it by changing admixture.

If overvibrated, fines on surface will going to call for shrinkage.

As from picture and shape it look like max structure area have form finish, overvibration cant be seen.

Increase the pouring rate and keep control on vibration.

Airation - admixture used in concrete generally release air in concrete, the more effect of airation seen in self compacting concretes or super fluid concretes. This is non controllable, or u can control it by changing admixture.

Although we are reducing amount of admixture 25%-20% and we are using M40 grade concreteOver vibration can cause the fine materials to get accumulate at surface and near to form face.

If overvibrated, fines on surface will going to call for shrinkage.

As from picture and shape it look like max structure area have form finish, overvibration cant be seen.

Increase the pouring rate and keep control on vibration.

Airation - admixture used in concrete generally release air in concrete, the more effect of airation seen in self compacting concretes or super fluid concretes. This is non controllable, or u can control it by changing admixture.

Shall u explain wt is the steel frame converting??

Attachments

Dnyan Deshmukh

Staff member

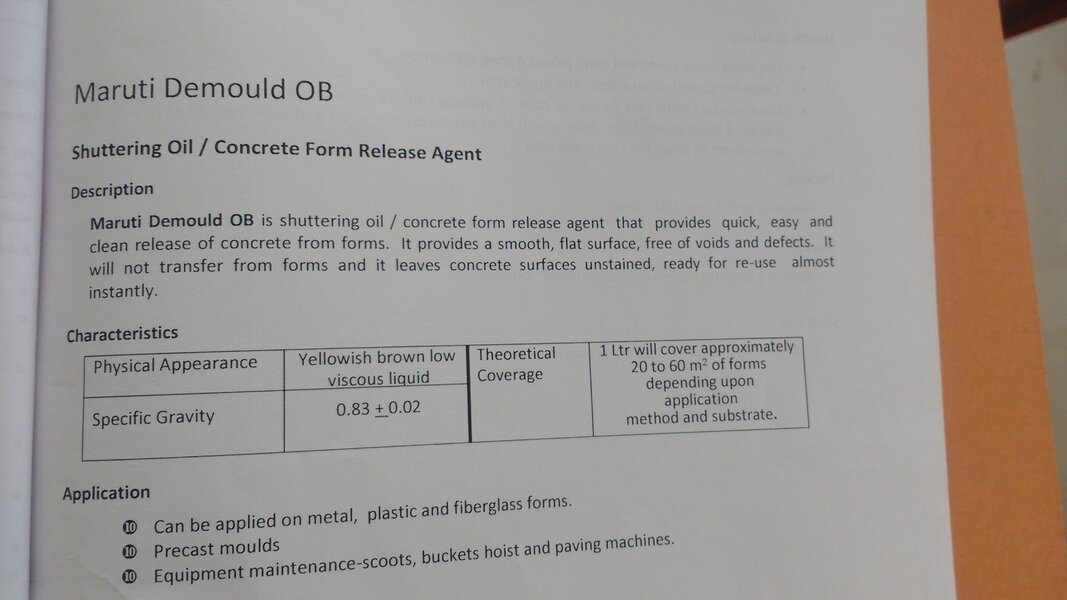

Which mould release oil / agent u are using.

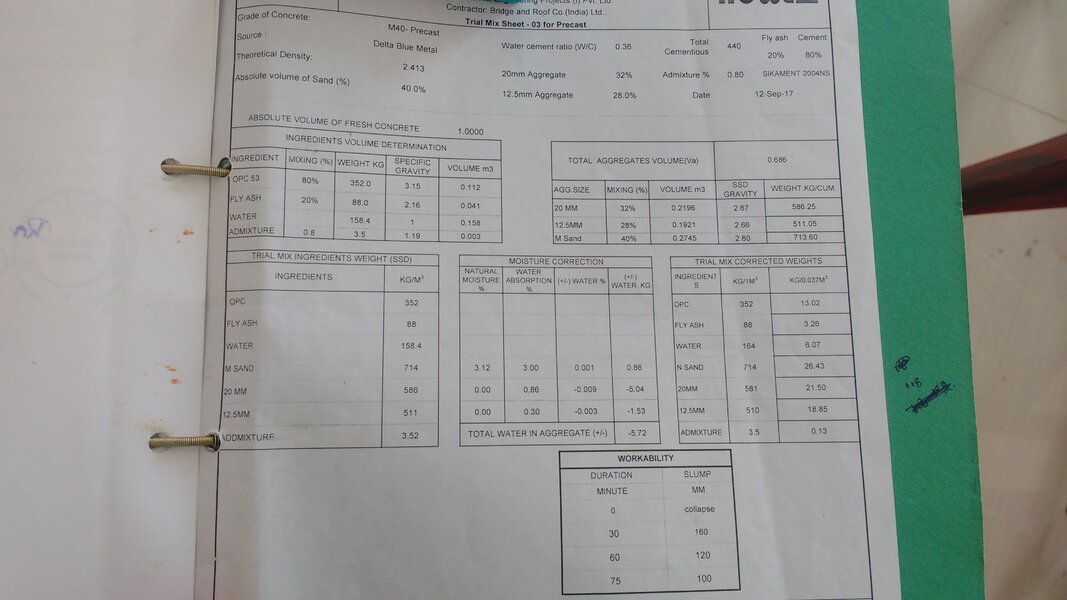

Message me details of mix design and moupd release agent through private conversation.

Message me details of mix design and moupd release agent through private conversation.

K Kiran

Senior Member

It may be formation of bleed channels due to over vibration. and surface voids that resulted from the migration of entrapped air (and to a lesser extent water) to the fresh concrete-form interface.

As mentioned above Kindly check for

form-releasing agents

Concrete Mix design

Air content of concrete

As mentioned above Kindly check for

form-releasing agents

Concrete Mix design

Air content of concrete

Dnyan Deshmukh

Staff member

I have inspected the images provided by you.

Your Formwork / mould quality is good, its water tight form.

Your concrete have the more water content, extra water is trying to escape out from the concrete surface, but due to water tight formwork. it is occupying the space on surface of concrete which is causing defect.

Airation might be problem with your Admixture (Admixture compatibility to be check with all brands of cement you use), Had you change the brand of cement or admixture.

A mould release agent (Shuttering oil) can also be culprit in forming air bubbles on the surface.

I see hardly any shrinkage cracks on surface of concrete - You are taking good care of concrete.

To reduce airation, change admixture or try to reduce admixture quantity and the slump of concrete too.

Keep the slump of concrete as low as possible, as this is big water tight structure and hope their is no congestion of reinforcement bars inside it.

Your Formwork / mould quality is good, its water tight form.

Your concrete have the more water content, extra water is trying to escape out from the concrete surface, but due to water tight formwork. it is occupying the space on surface of concrete which is causing defect.

Airation might be problem with your Admixture (Admixture compatibility to be check with all brands of cement you use), Had you change the brand of cement or admixture.

A mould release agent (Shuttering oil) can also be culprit in forming air bubbles on the surface.

I see hardly any shrinkage cracks on surface of concrete - You are taking good care of concrete.

To reduce airation, change admixture or try to reduce admixture quantity and the slump of concrete too.

Keep the slump of concrete as low as possible, as this is big water tight structure and hope their is no congestion of reinforcement bars inside it.

Permatech

Newbie

Dnyan Deshmukh

Staff member

Is concrete produce with your mix design gives volume of 1 cum exactly.

If its design by you, cross check the specific gravities of all aggregates (Though you are using 40% FA, it might be more compare to volume, if SG is not calculated properly)

Try changing admixture, the cause most probably due to admixture you used.

Airation in most of the cases caused by admixture.

For better workability and cohesive mix increase 20mm content and reduce 10mm, this will reduce the surface area (It will also improve the strength parameter).

I can not say anything on shuttering oil, as i am not expert in it (Better you try different mould release agent and check the difference between them, it will give you idea, if oil is culprit. You can ask for sample oil from local suppliers and do test)

If its design by you, cross check the specific gravities of all aggregates (Though you are using 40% FA, it might be more compare to volume, if SG is not calculated properly)

Try changing admixture, the cause most probably due to admixture you used.

Airation in most of the cases caused by admixture.

For better workability and cohesive mix increase 20mm content and reduce 10mm, this will reduce the surface area (It will also improve the strength parameter).

I can not say anything on shuttering oil, as i am not expert in it (Better you try different mould release agent and check the difference between them, it will give you idea, if oil is culprit. You can ask for sample oil from local suppliers and do test)

K Kiran

Senior Member

As mentioned above @Dnyan Deshmukh kindly check for mix design calculation sheet , as per attached sheet density of concrete is below 2400kg/cum.

please recheck aggregate grading part, correction can be done accordingly. Enough fine particle available in your concrete, you can think off increasing the 20mm aggregate

Always try to maintain measurable initial slump( as initial slump is collapse) , there may be possibilities of segregation or bleeding.

please recheck aggregate grading part, correction can be done accordingly. Enough fine particle available in your concrete, you can think off increasing the 20mm aggregate

Always try to maintain measurable initial slump( as initial slump is collapse) , there may be possibilities of segregation or bleeding.

Last edited:

Similar threads

- Replies

- 0

- Views

- 32

- Replies

- 0

- Views

- 43

- Replies

- 0

- Views

- 62

- Replies

- 0

- Views

- 58