While reading IS code, we should read it carefully to understand what does it mean.

It states - as a general guidance, the maximum permissible free fall of concrete may be taken as a 1.5 meter.

it does not say you should consider as same but in absence of data, you may take this.

IS codes do cover all aspects of the construction and those are made to be practically applicable for even construction of single house to a mass housing projects.

Back in time i saw something special about free fall height, just did search and pasting lines from search on google.

As published in Concrete International, a publication of the American Concrete Institute

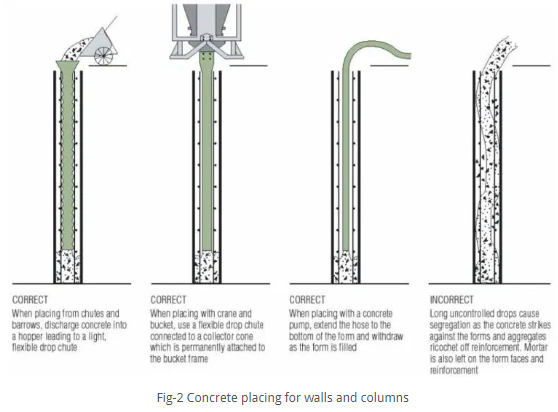

Sometimes specifiers and inspectors dictate the maximum free-fall distance of concrete because they believe limiting free fall is necessary to minimize concrete segregation. Usually they limit the free-fall distance to 3 to 5 ft (0.9 to 1.5 m), but occasionally the limit is as little as 2 ft (0.6 m). Neither ACI 301- 99, “Specifications for Structural Concrete,” nor ACI 318-02, “Building Code Requirements for Structural Concrete,” limit the maximum distance concrete can free fall. ACI 304R-00, “Guide for Measuring, Mixing, Transporting, and Placing Concrete,” states that “if forms are sufficiently open and clear so that the concrete is not disturbed in a vertical fall into place, direct discharge without the use of hoppers, trunks, or chutes is favorable.” ACI 301, 304, and 318, however, all require placing the concrete at or near its final position to avoid segregation due to flowing.

In 1999, the Federal Highway Administration eliminated its 25 ft (8 m) free-fall limitation and now allows unlimited free fall of concrete. Free fall of concrete from heights of up to 150 ft (46 m), directly over reinforcement or at high slumps, does not cause segregation or reduce compressive strength. Restricting free-fall heights does decrease concrete production rates, which increases owners’ costs without increasing concrete quality.

Hopefully now your question would have got one more aspect to think on what should be free fall height of concrete.

I personally do pouring of concrete from height of 2.4 meter.

For heights like 4.2 meters, we initially used tremie pipe for casting of walls and columns but later on we also made window in form to facilitate the work. (at this project we had concrete boom pacer and cranes to do this job).