Standard Consistency Test for Cement

Ref : IS 4031 (part IV)

Purpose : To determine the standard consistency for finding initial and final setting time of Ordinary Portland cement.

Apparatus:

Vicat apparatus (mould dia - 80mm & height - 40mm)

Weights & balance

Trowel

Plunger (10mm dia and 50mm long)

Significance : It is a parameter which is used to find out initial and final setting time and soundness of cement. This gives percentage of water required to produce a cement paste of standard consistency.

Test Procedure:

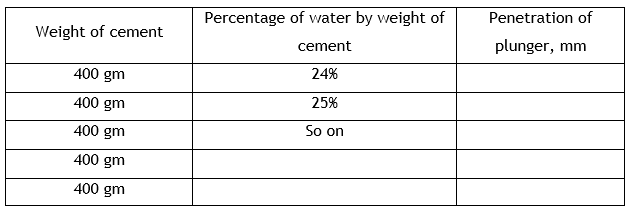

- Take about 400gm of cement and prepare a paste with a weighed quantity of water, (say 25% to 35% by weight of cement)

- The paste must be prepared in a standard manner and filled in to the vicat mould within 3 to 5 minutes.

- After completely filling the mould, shake the mould to expel air

- A plunger attached and brought down to touch the surface of the paste in the test block and quickly released allowing it to sink in to the paste by its own weight

- Take the reading by noting the depth of penetration of the plunger

- Similarly, conduct trails with higher and higher W/C ratio till such time the plunger penetrates for a depth of 5 to 7mm from the bottom

- The particular percentage of water which allows the plunger to penetrate only to a depth of 5 to 7mm from the bottom is known as the percentage of water required to produce a cement paste of standard consistency

- This percentage is usually denoted as ‘P’

Range : General range of standard consistency is 25% to 35%

Frequency : Every batch received at site.