The process of selecting suitable ingredients for concrete

The process of selecting suitable ingredients of concrete and determining their relative amounts with the objective of producing a concrete of the required, strength, durability, and workability as economically as possible, is termed the concrete mix design. The proportioning of ingredient of concrete is governed by the required performance of concrete in 2 states, namely the plastic and the hardened states. If the plastic concrete is not workable, it cannot be properly placed and compacted. The property of workability, therefore, becomes of vital importance. The compressive strength of hardened concrete which is generally considered to be an index of its other properties, depends upon many factors, e.g. quality and quantity of cement, water and aggregates; batching and mixing; placing, compaction and curing. The cost of concrete is made up of the cost of materials, plant and labour. The variations in the cost of materials arise from the fact that the cement is several times costly than the aggregate, thus the aim is to produce as lean a mix as possible. From technical point of view the rich mixes may lead to high shrinkage and cracking in the structural concrete, and to evolution of high heat of hydration in mass concrete which may cause cracking.

In this study, we have used grit and crushed sand for the design mix and found the characteristic compressive strength at 3,7 and 28 days respectively. The mix design has been done as per IS:10262.

Advantages of mix design

Mix design aims to achieve good quality concrete at site economically.

Quality concrete means

Economy in cement consumption

It is possible to save up to 15% of cement for M20 grade of concrete with the help of concrete mix design. In fact higher the grade of concrete more are the savings. Lower cement content also results in lower heat of hydration and hence reduces shrinkage cracks.

Best use of available materials:

Site conditions often restrict the quality and quantity of ingredient materials. Concrete mix design offers a lot of flexibility on type of aggregates to be used in mix design. Mix design can give an economical solution based on the available materials if they meet the basic IS requirements. This can lead to saving in transportation costs from longer distances.

Other properties:

Mix design can help us to achieve form finishes, high early strengths for early deshuttering, concrete with better flexural strengths, concrete with pumpability and concrete with lower densities.

Requirements of mix design

Concrete mix design is the method of correct proportioning of ingredients of concrete, in order to optimize the above properties of concrete as per site requirements.

The site engineer should give following information while giving material for mix design to the mix design laboratory: -

Following factors indicate degree of control at site: -

Batching – weigh batching / volume batching.

Type of aggregates – whether mixed graded aggregate will be used or 20mm, 10mm aggregates will be used separately.

Testing of concrete – whether casting & testing of concrete cubes will be done regularly at site.

Source of aggregate – whether sources of sand and aggregate will be standardized or likely to change frequently.

Supervision – whether qualified staff will be present to supervise concreting workand make necessary corrections e.g. correction for moisture in sand and changes in material properties.

Factors affecting the choice of mix proportions

The various factors affecting the mix design are:

Compressive strength

It is one of the most important properties of concrete and influences many other describable properties of the hardened concrete. The mean compressive strength required at a specific age, usually 28 days, determines the nominal water-cement ratio of the mix. The other factor affecting the strength of concrete at a given age and cured at a prescribed temperature is the degree of compaction. According to Abraham’s law the strength of fully compacted concrete is inversely proportional to the water-cement ratio.

Workability

The degree of workability required depends on three factors. These are the size of the section to be concreted, the amount of reinforcement, and the method of compaction to be used. For the narrow and complicated section with numerous corners or inaccessible parts, the concrete must have a high workability so that full compaction can be achieved with a reasonable amount of effort. This also applies to the embedded steel sections. The desired workability depends on the compacting equipment available at the site.

Durability

The durability of concrete is its resistance to the aggressive environmental conditions. High strength concrete is generally more durable than low strength concrete. In the situations when the high strength is not necessary but the conditions of exposure are such that high durability is vital, the durability requirement will determine the water-cement ratio to be used.

Maximum nominal size of aggregate

In general, larger the maximum size of aggregate, smaller is the cement requirement for a particular water-cement ratio, because the workability of concrete increases with increase in maximum size of the aggregate. However, the compressive strength tends to increase with the decrease in size of aggregate.

IS 456:2000 and IS 1343:1980 recommend that the nominal size of the aggregate should be as large as possible.

Grading and type of aggregate

The grading of aggregate influences the mix proportions for a specified workability and water-cement ratio. Coarser the grading leaner will be mix which can be used. Very lean mix is not desirable since it does not contain enough finer material to make the concrete cohesive. The type of aggregate influences strongly the aggregate-cement ratio for the desired workability and stipulated water cement ratio. An important feature of a satisfactory aggregate is the uniformity of the grading which can be achieved by mixing different size fractions.

Quality Control

The degree of control can be estimated statistically by the variations in test results. The variation in strength results from the variations in the properties of the mix ingredients and lack of control of accuracy in batching, mixing, placing, curing and testing. The lower the difference between the mean and minimum strengths of the mix lower will be the cement-content required. The factor controlling this difference is termed as quality control.

Mix Proportion designations

The common method of expressing the proportions of ingredients of a concrete mix is in the terms of parts or ratios of cement, fine and coarse aggregates. For e.g., a concrete mix of proportions 1:2:4 means that cement, fine and coarse aggregate are in the ratio 1:2:4 or the mix contains one part of cement, two parts of fine aggregate and four parts of coarse aggregate. The proportions are either by volume or by mass. The water-cement ratio is usually expressed in mass

Factors to be considered for mix design

Mix Design Procedure as per IS:10262.

S = specific gravity of cement

W = Mass of water per cubic metre of concrete, kg

C = mass of cement per cubic metre of concrete, kg

p = ratio of fine aggregate to total aggregate by absolute volume

f, C = total masses of fine and coarse aggregates, per cubic metre of concrete, respectively, kg, and

S, S = specific gravities of saturated surface dry fine and coarse aggregates, respectively

Determine the concrete mix proportions for the first trial mix.

Prepare the concrete using the calculated proportions and cast three cubes of 150 mm size and test them wet after 28-days moist curing and check for the strength.

Prepare trial mixes with suitable adjustments till the final mix proportions are arrived at.

MIX DESIGN OF CONCRETE AS PER IS:10262.

Step 1: Design Stipulations

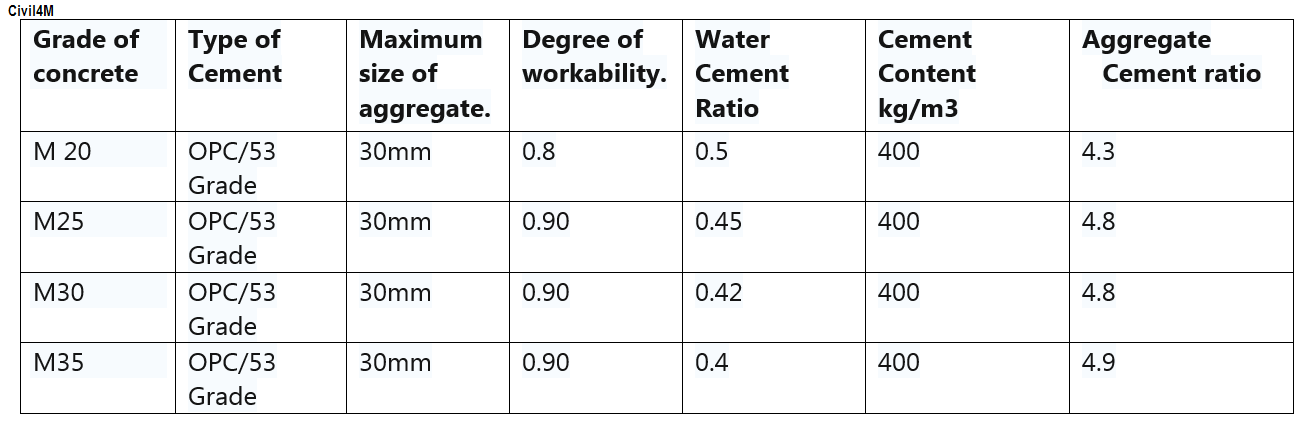

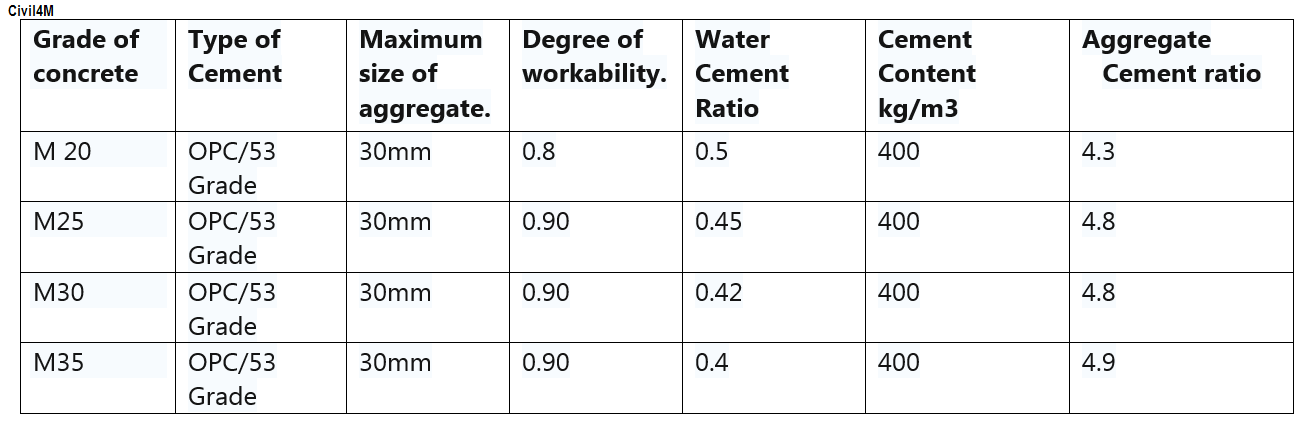

Table – 1

Step 2: Test Data For Materials

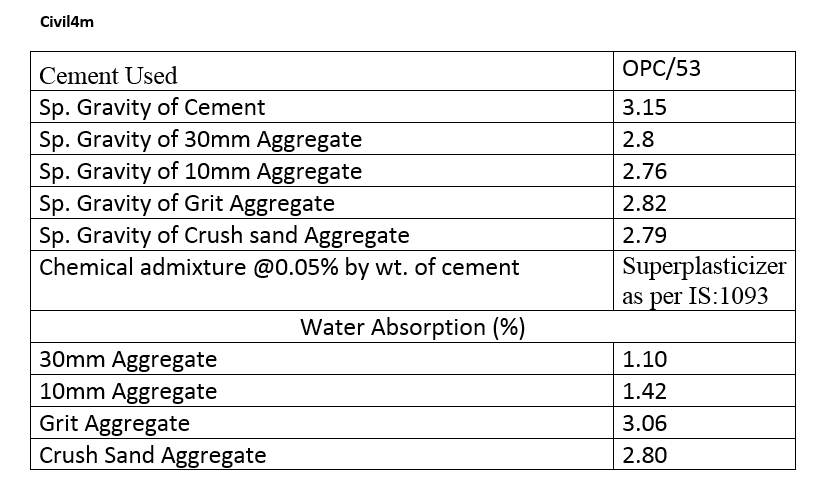

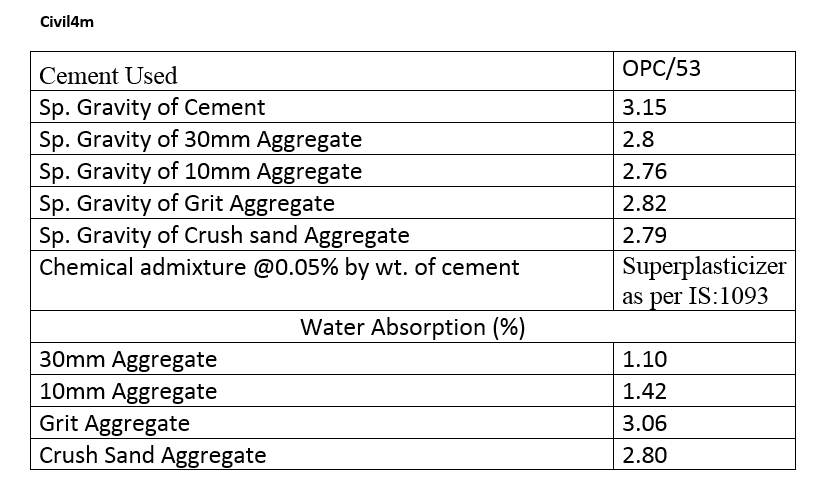

Table – 2

Step 3: Sieve Analysis

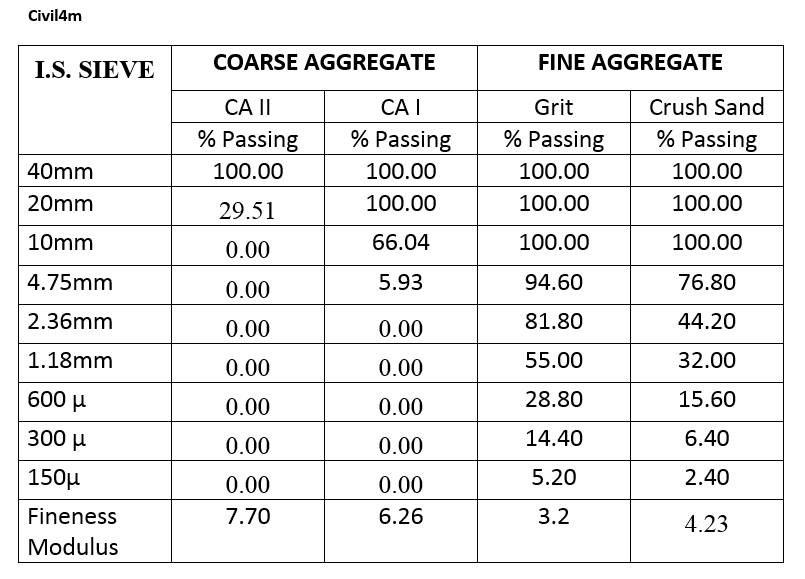

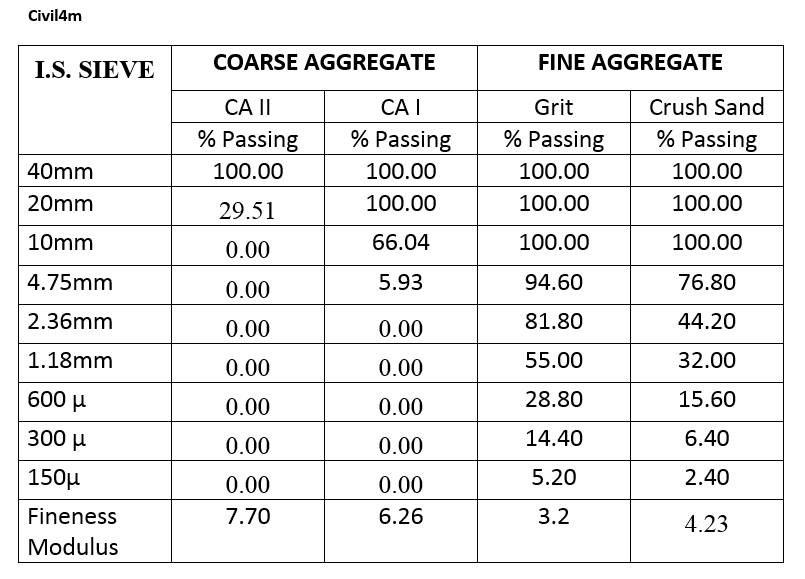

Table – 3

Step 4: Target Strength Of Concrete

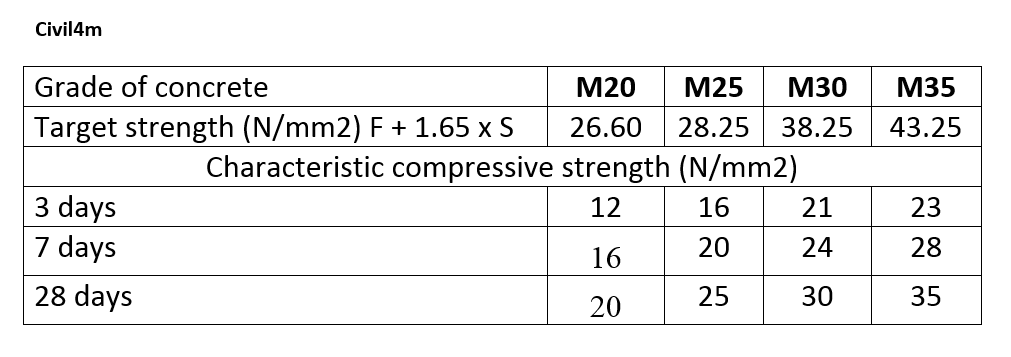

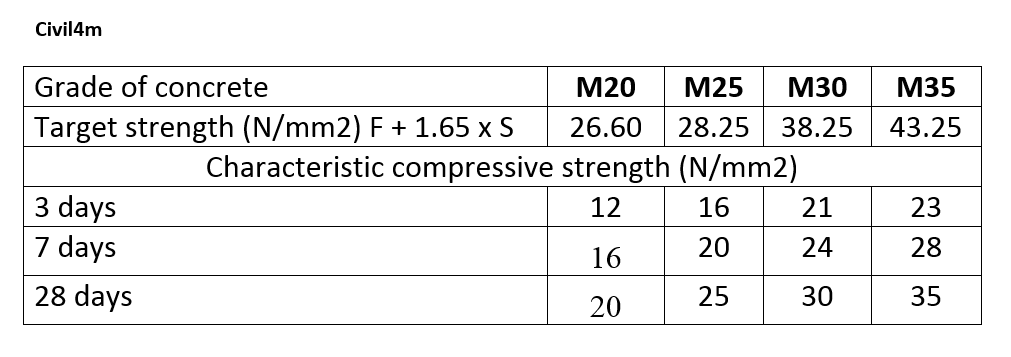

Table – 4

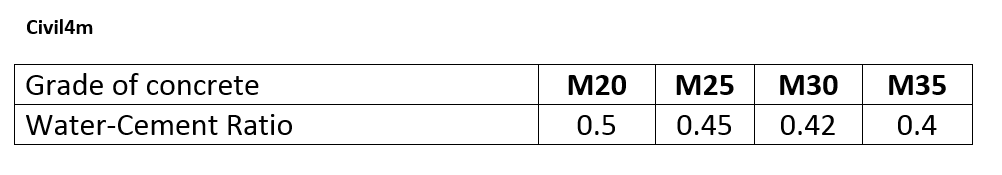

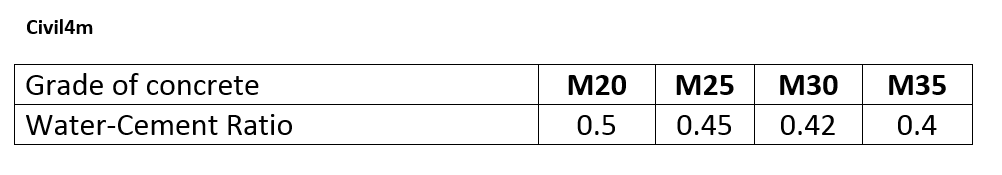

Step 5: Selection Of Water- Cement Ratio

Step 6: Proportion Of Fine Aggregate and Coarse Aggregates

Table – 6

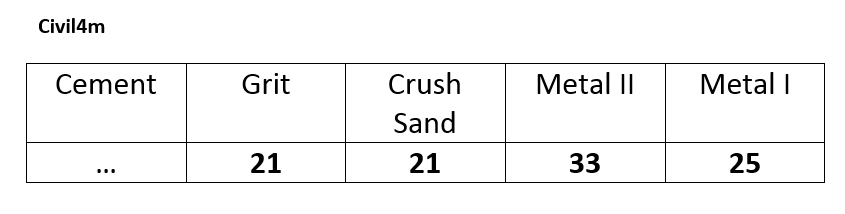

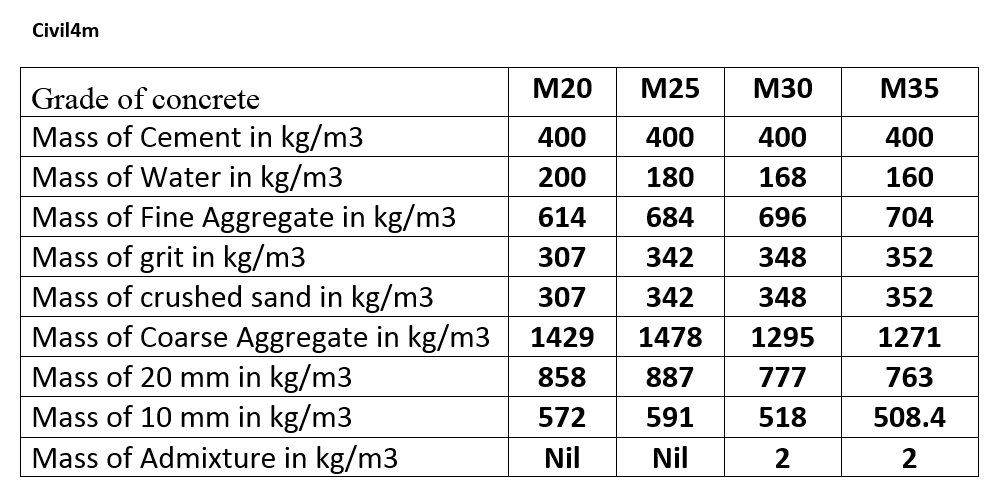

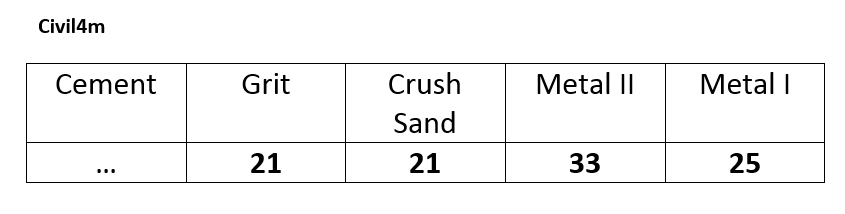

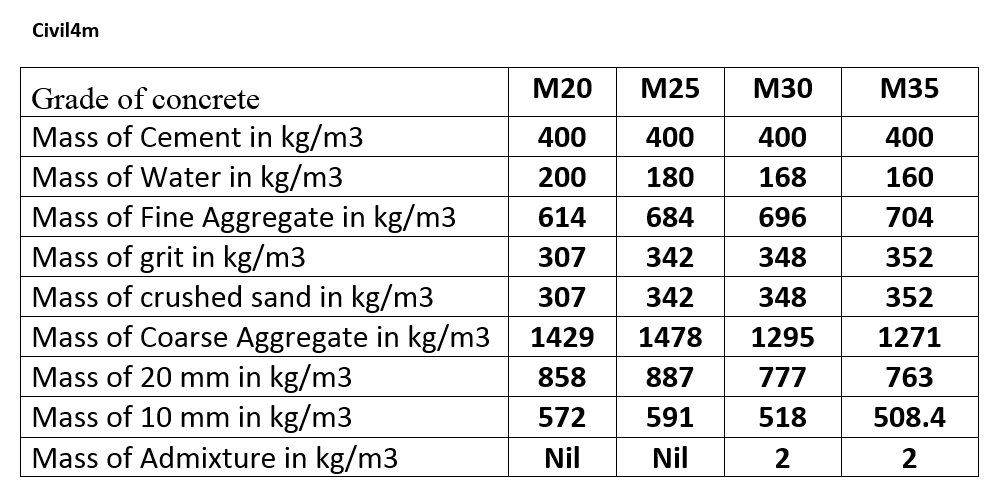

Step 7: Mix Proportions for One Cum of Concrete (SSD Condition)

Table – 7

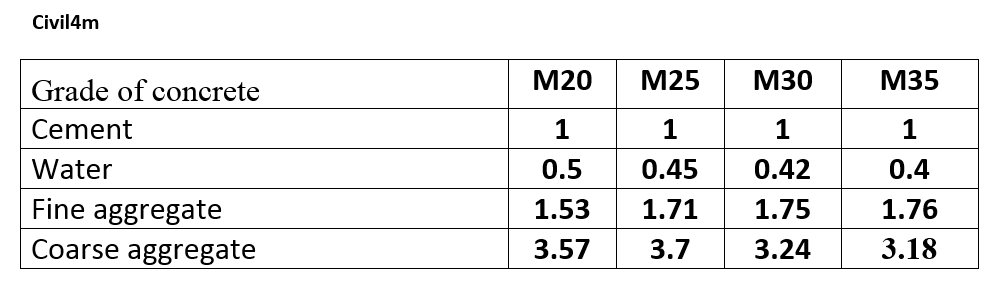

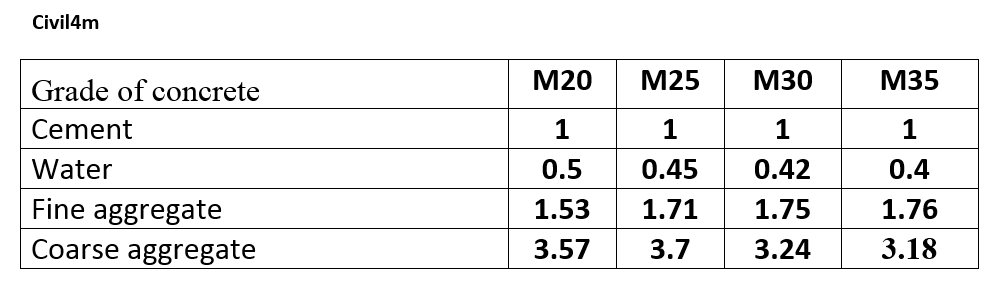

Step 8: Mix Proportions

Table – 8

Conclusion

The results of mix design indicate that crushed sand can also make as good a concrete as that made of natural sand.The compressive strength obtained is same as of normal mixes. In fact use of crushed sand will become inevitable in near future because of dwindling sources of natural sand. Crushed sand particle though shaped, does not have the spherical shape of natural sand. Hence the crushed sand will have greater water demand than that of natural sand resulting in slightly higher cement consumption. However, if crushed sand is properly graded with adequate fines the mix may have lower water demand when compared to poorly graded natural sand. Besides crushed sand can afford better control on gradation when compared to natural sand. Hence crushed sand may become an economical option if good quality natural sand is not available.

The process of selecting suitable ingredients of concrete and determining their relative amounts with the objective of producing a concrete of the required, strength, durability, and workability as economically as possible, is termed the concrete mix design. The proportioning of ingredient of concrete is governed by the required performance of concrete in 2 states, namely the plastic and the hardened states. If the plastic concrete is not workable, it cannot be properly placed and compacted. The property of workability, therefore, becomes of vital importance. The compressive strength of hardened concrete which is generally considered to be an index of its other properties, depends upon many factors, e.g. quality and quantity of cement, water and aggregates; batching and mixing; placing, compaction and curing. The cost of concrete is made up of the cost of materials, plant and labour. The variations in the cost of materials arise from the fact that the cement is several times costly than the aggregate, thus the aim is to produce as lean a mix as possible. From technical point of view the rich mixes may lead to high shrinkage and cracking in the structural concrete, and to evolution of high heat of hydration in mass concrete which may cause cracking.

In this study, we have used grit and crushed sand for the design mix and found the characteristic compressive strength at 3,7 and 28 days respectively. The mix design has been done as per IS:10262.

Advantages of mix design

Mix design aims to achieve good quality concrete at site economically.

Quality concrete means

- Better strength

- Better imperviousness and durability

- Dense and homogeneous concrete

Economy in cement consumption

It is possible to save up to 15% of cement for M20 grade of concrete with the help of concrete mix design. In fact higher the grade of concrete more are the savings. Lower cement content also results in lower heat of hydration and hence reduces shrinkage cracks.

Best use of available materials:

Site conditions often restrict the quality and quantity of ingredient materials. Concrete mix design offers a lot of flexibility on type of aggregates to be used in mix design. Mix design can give an economical solution based on the available materials if they meet the basic IS requirements. This can lead to saving in transportation costs from longer distances.

Other properties:

Mix design can help us to achieve form finishes, high early strengths for early deshuttering, concrete with better flexural strengths, concrete with pumpability and concrete with lower densities.

Requirements of mix design

Concrete mix design is the method of correct proportioning of ingredients of concrete, in order to optimize the above properties of concrete as per site requirements.

The site engineer should give following information while giving material for mix design to the mix design laboratory: -

- Grade of concrete (the characteristic strength)

- Workability requirement in terms of slump

- Other properties (if required): -

- Retardation of initial set (to avoid cold joints in case of longer leads or for ready-mix concrete)

- Slump retention (in case of ready mix concrete)

- Pumpability (In case of ready mix concrete)

- Acceleration of strength (for precast members or where early de-shuttering is desired)

- Flexural strength (normally required for concrete pavements)

- Ascertain whether condition of exposure to concrete is mild, moderate severe or very severe. Proper investigation of soil should be done to ascertain presence of sulphates &chlorides, in case of doubt.

- What is the degree of control at site?

Following factors indicate degree of control at site: -

Batching – weigh batching / volume batching.

Type of aggregates – whether mixed graded aggregate will be used or 20mm, 10mm aggregates will be used separately.

Testing of concrete – whether casting & testing of concrete cubes will be done regularly at site.

Source of aggregate – whether sources of sand and aggregate will be standardized or likely to change frequently.

Supervision – whether qualified staff will be present to supervise concreting workand make necessary corrections e.g. correction for moisture in sand and changes in material properties.

Factors affecting the choice of mix proportions

The various factors affecting the mix design are:

Compressive strength

It is one of the most important properties of concrete and influences many other describable properties of the hardened concrete. The mean compressive strength required at a specific age, usually 28 days, determines the nominal water-cement ratio of the mix. The other factor affecting the strength of concrete at a given age and cured at a prescribed temperature is the degree of compaction. According to Abraham’s law the strength of fully compacted concrete is inversely proportional to the water-cement ratio.

Workability

The degree of workability required depends on three factors. These are the size of the section to be concreted, the amount of reinforcement, and the method of compaction to be used. For the narrow and complicated section with numerous corners or inaccessible parts, the concrete must have a high workability so that full compaction can be achieved with a reasonable amount of effort. This also applies to the embedded steel sections. The desired workability depends on the compacting equipment available at the site.

Durability

The durability of concrete is its resistance to the aggressive environmental conditions. High strength concrete is generally more durable than low strength concrete. In the situations when the high strength is not necessary but the conditions of exposure are such that high durability is vital, the durability requirement will determine the water-cement ratio to be used.

Maximum nominal size of aggregate

In general, larger the maximum size of aggregate, smaller is the cement requirement for a particular water-cement ratio, because the workability of concrete increases with increase in maximum size of the aggregate. However, the compressive strength tends to increase with the decrease in size of aggregate.

IS 456:2000 and IS 1343:1980 recommend that the nominal size of the aggregate should be as large as possible.

Grading and type of aggregate

The grading of aggregate influences the mix proportions for a specified workability and water-cement ratio. Coarser the grading leaner will be mix which can be used. Very lean mix is not desirable since it does not contain enough finer material to make the concrete cohesive. The type of aggregate influences strongly the aggregate-cement ratio for the desired workability and stipulated water cement ratio. An important feature of a satisfactory aggregate is the uniformity of the grading which can be achieved by mixing different size fractions.

Quality Control

The degree of control can be estimated statistically by the variations in test results. The variation in strength results from the variations in the properties of the mix ingredients and lack of control of accuracy in batching, mixing, placing, curing and testing. The lower the difference between the mean and minimum strengths of the mix lower will be the cement-content required. The factor controlling this difference is termed as quality control.

Mix Proportion designations

The common method of expressing the proportions of ingredients of a concrete mix is in the terms of parts or ratios of cement, fine and coarse aggregates. For e.g., a concrete mix of proportions 1:2:4 means that cement, fine and coarse aggregate are in the ratio 1:2:4 or the mix contains one part of cement, two parts of fine aggregate and four parts of coarse aggregate. The proportions are either by volume or by mass. The water-cement ratio is usually expressed in mass

Factors to be considered for mix design

- The grade designation giving the characteristic strength requirement of concrete.

- The type of cement influences the rate of development of compressive strength of concrete.

- Maximum nominal size of aggregates to be used in concrete may be as large as possible within the limits prescribed by IS 456:2000.

- The cement content is to be limited from shrinkage, cracking and creep.

- The workability of concrete for satisfactory placing and compaction is related to the size and shape of section, quantity and spacing of reinforcement and technique used for transportation, placing and compaction.

Mix Design Procedure as per IS:10262.

- Determine the mean target strength from the specified characteristic compressive strength at 28-day find the level of quality control. f = f + 1.65 x S , where S is the standard deviation obtained from the Table of approximate contents given after the design mix.

- Obtain the water cement ratio for the desired mean target using the emperical relationship between compressive strength and water cement ratio so chosen is checked against the limiting water cement ratio. The water cement ratio so chosen is checked against the limiting water cement ratio for the requirements of durability given in table and adopts the lower of the two values.

- Estimate the amount of entrapped air for maximum nominal size of the aggregate from the table.

- Select the water content, for the required workability and maximum size of aggregates (for aggregates in saturated surface dry condition) from table.

- Determine the percentage of fine aggregate in total aggregate by absolute volume from table for the concrete using crushed coarse aggregate.

- Adjust the values of water content and percentage of sand as provided in the table for any difference in workability, water cement ratio, grading of fine aggregate and for rounded aggregate the values are given in table.

- Calculate the cement content form the water-cement ratio and the final water content as arrived after adjustment. Check the cement against the minimum cement content from the requirements of the durability, and greater of the two values is adopted.

- From the quantities of water and cement per unit volume of concrete and the percentage of sand already determined in steps 6 and 7 above, calculate the content of coarse and fine aggregates per unit volume of concrete from the following relations:

S = specific gravity of cement

W = Mass of water per cubic metre of concrete, kg

C = mass of cement per cubic metre of concrete, kg

p = ratio of fine aggregate to total aggregate by absolute volume

f, C = total masses of fine and coarse aggregates, per cubic metre of concrete, respectively, kg, and

S, S = specific gravities of saturated surface dry fine and coarse aggregates, respectively

Determine the concrete mix proportions for the first trial mix.

Prepare the concrete using the calculated proportions and cast three cubes of 150 mm size and test them wet after 28-days moist curing and check for the strength.

Prepare trial mixes with suitable adjustments till the final mix proportions are arrived at.

MIX DESIGN OF CONCRETE AS PER IS:10262.

Step 1: Design Stipulations

Table – 1

Step 2: Test Data For Materials

Table – 2

Step 3: Sieve Analysis

Table – 3

Step 4: Target Strength Of Concrete

Table – 4

Step 5: Selection Of Water- Cement Ratio

Step 6: Proportion Of Fine Aggregate and Coarse Aggregates

Table – 6

Step 7: Mix Proportions for One Cum of Concrete (SSD Condition)

Table – 7

Step 8: Mix Proportions

Table – 8

Conclusion

The results of mix design indicate that crushed sand can also make as good a concrete as that made of natural sand.The compressive strength obtained is same as of normal mixes. In fact use of crushed sand will become inevitable in near future because of dwindling sources of natural sand. Crushed sand particle though shaped, does not have the spherical shape of natural sand. Hence the crushed sand will have greater water demand than that of natural sand resulting in slightly higher cement consumption. However, if crushed sand is properly graded with adequate fines the mix may have lower water demand when compared to poorly graded natural sand. Besides crushed sand can afford better control on gradation when compared to natural sand. Hence crushed sand may become an economical option if good quality natural sand is not available.