Concrete mix designing is a vital part of any construction activity.

Why we do mix design when proportions for material are listed in IS codes for various grades?

The listed mixes have more cement content than required and have fix properties like workability, retention time etc.

In order to make use of available material and optimize the cost of concrete, mix designing is done.

It allow us to play with all the properties of concrete by testing theories via trials.

In Concrete mix design, crucial part is taking proportion of aggregates.

How one can know the mix is under sanded or over sanded or may have voids in it etc.

To analyze this we do check the gradation of aggregates according to relevant standard for conformity.

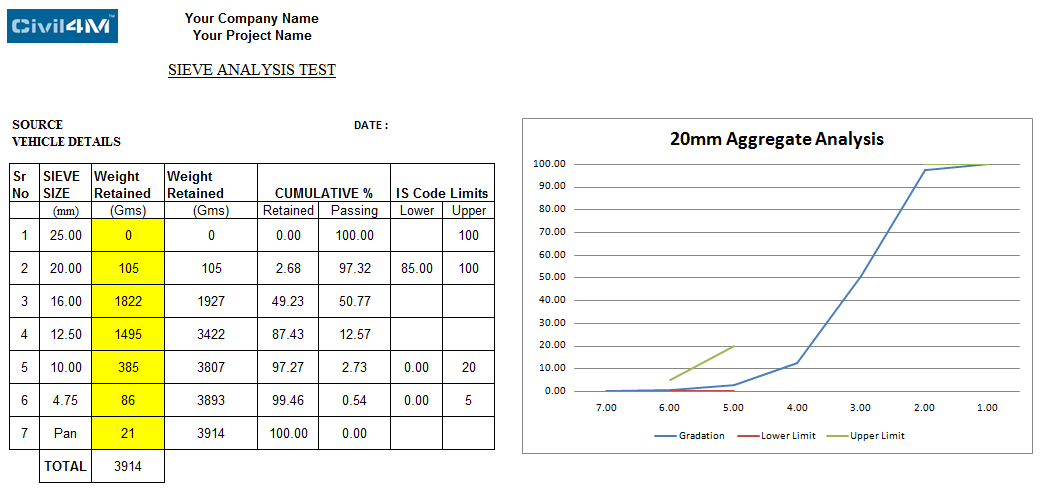

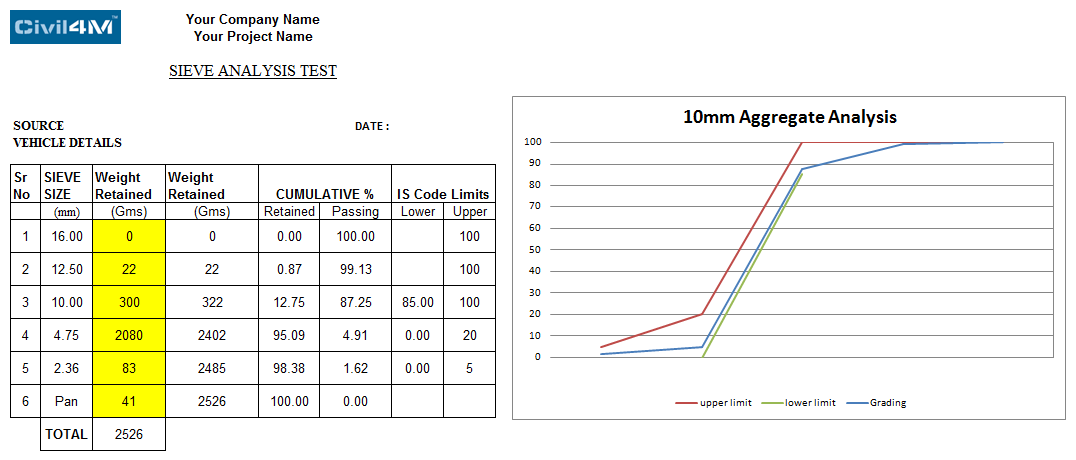

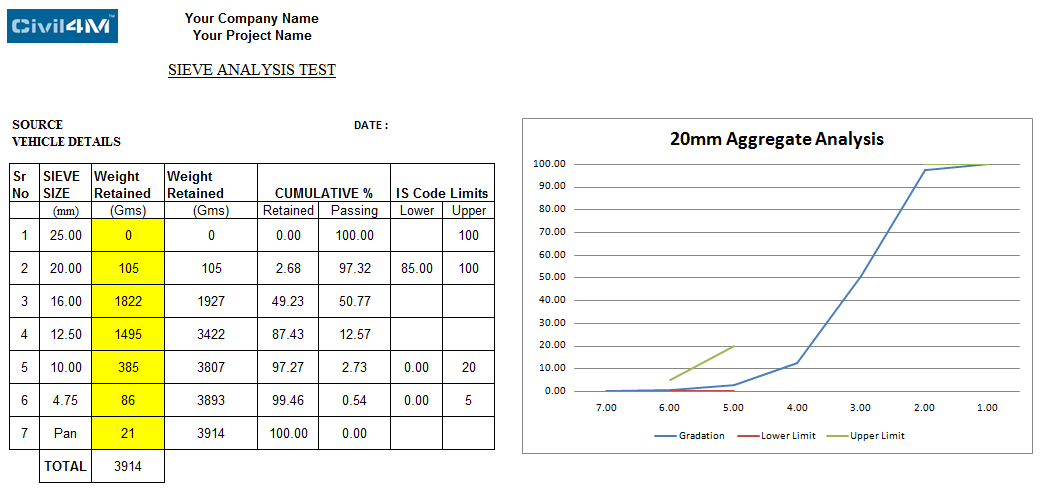

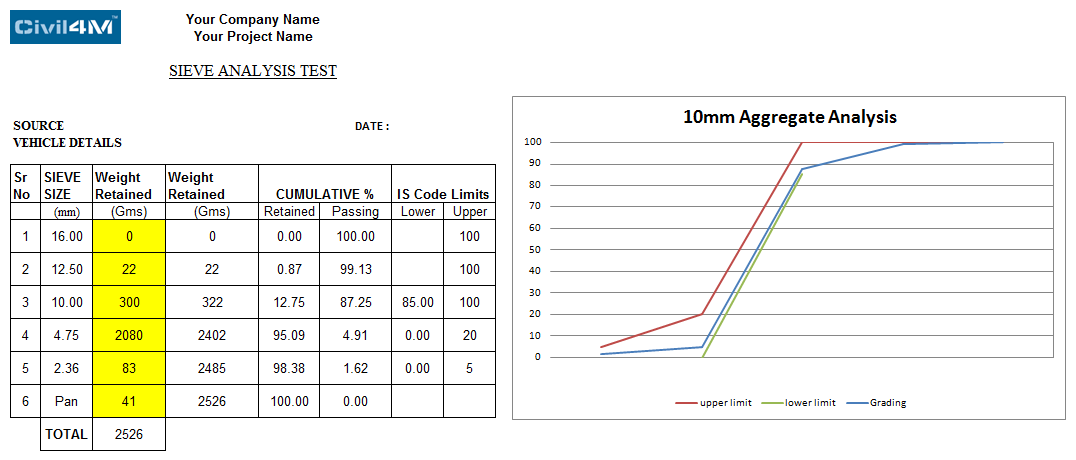

Course Aggregates are single size aggregates like 20 mm, 10mm - We require to verify the size by doing sieve analysis.

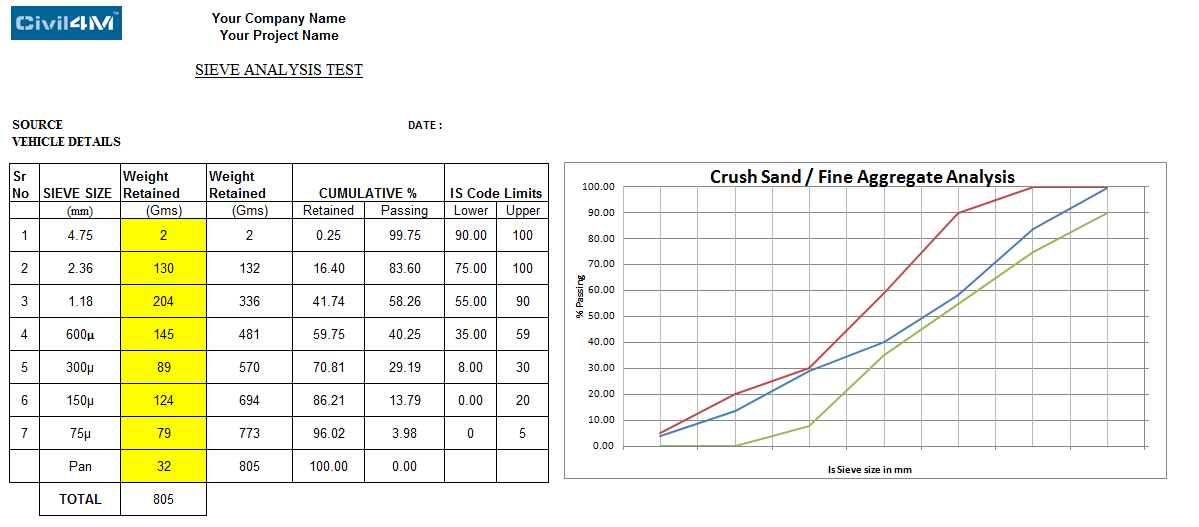

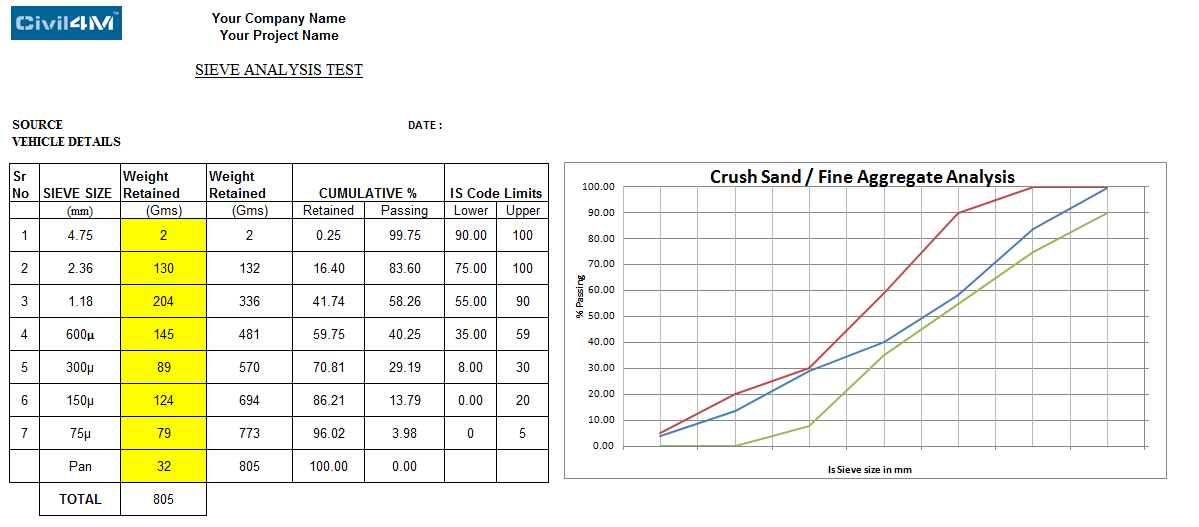

Fine aggregates have multiple sizes graded into it. - need to analyze same way.

To analyze we do sieve analysis

Below are example

I think all of you know how to do a sieve analysis, if no then reply here, i will post informative thread on it.

Above pictures have everything automated in it.

You need to put the weights of retained materials on every sieve in yellow box (File is attached for you ).

).

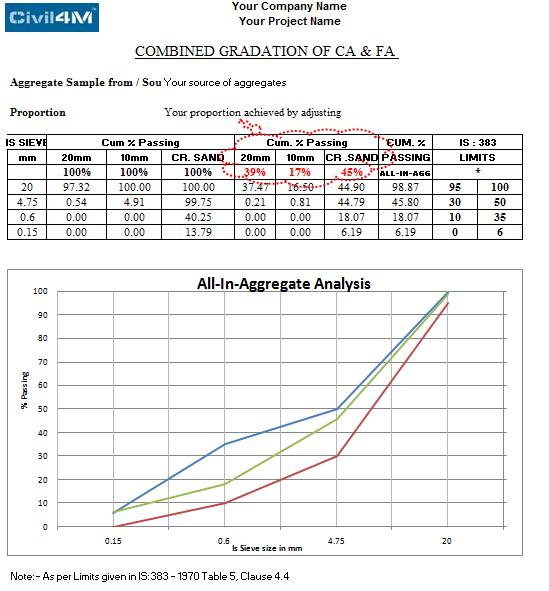

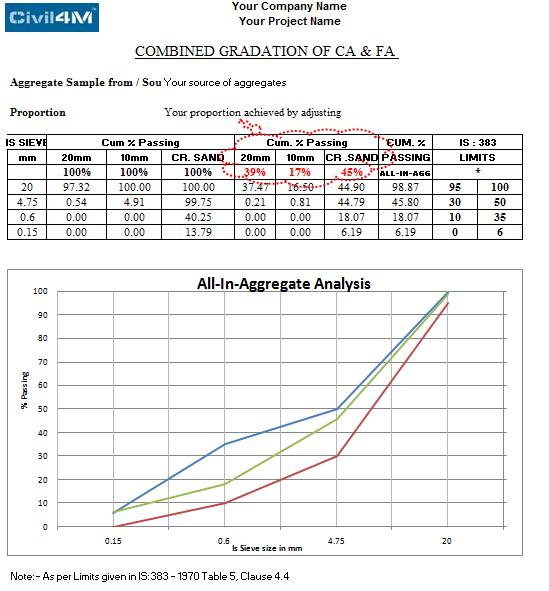

Once we did the sieve analysis of all aggregates, Next step is to check the combine gradation of aggregates.

In General people use to take the proportion for mix designs base on their previous experience.

See below image, i have mark area with a red cloud where u can adjust the % of each aggregate to ensure the combine gradation falls within the limit specified by IS Code by seeing the graph ( You may use your relevant standard limitations)

Once you adjusted the proportion of aggregate to fall it inside the limits, you can now move further to mix design.

This post is just related to how to do combine gradation only.

If you have any queries you can post by replying here.

Why we do mix design when proportions for material are listed in IS codes for various grades?

The listed mixes have more cement content than required and have fix properties like workability, retention time etc.

In order to make use of available material and optimize the cost of concrete, mix designing is done.

It allow us to play with all the properties of concrete by testing theories via trials.

In Concrete mix design, crucial part is taking proportion of aggregates.

How one can know the mix is under sanded or over sanded or may have voids in it etc.

To analyze this we do check the gradation of aggregates according to relevant standard for conformity.

Course Aggregates are single size aggregates like 20 mm, 10mm - We require to verify the size by doing sieve analysis.

Fine aggregates have multiple sizes graded into it. - need to analyze same way.

To analyze we do sieve analysis

Below are example

I think all of you know how to do a sieve analysis, if no then reply here, i will post informative thread on it.

Above pictures have everything automated in it.

You need to put the weights of retained materials on every sieve in yellow box (File is attached for you

Once we did the sieve analysis of all aggregates, Next step is to check the combine gradation of aggregates.

In General people use to take the proportion for mix designs base on their previous experience.

See below image, i have mark area with a red cloud where u can adjust the % of each aggregate to ensure the combine gradation falls within the limit specified by IS Code by seeing the graph ( You may use your relevant standard limitations)

Once you adjusted the proportion of aggregate to fall it inside the limits, you can now move further to mix design.

This post is just related to how to do combine gradation only.

If you have any queries you can post by replying here.