Quality of Reinforcement Steel Bars used for Construction of RCC Structure.

When a lot of steel received at site, First check the Manufacturer test certificate for its actual properties.

With each lot of steel, manufacturer should send a test certificate of same lot for test done at their laboratory.

Check for grade of steel mention in certificate and is as per the order or not.

Steel bars may have rusting on it, do check closely to know either it is acceptable or not.

Steel received should be free from any contamination like, mud, dust, oil and any other foreign material etc.

Bars should not have splits and any other deformation on it.

Causes of Rusting:

Primary steel which is made from pure iron ore are likely to get rusted quicker compare to secondary steel.

Bars may get rusted due to contact with water or air and atmospheric condition.

A brownish bars showing little rusting due to weathering are good for use.

Small amount of rust is good for bonding of steel and concrete.

If excessive scaling observed on the surface of bar, it should not be accepted.

Do Check for brand of steel, diameter and grade of steel embossed on steel bars.

Cut the samples of 1 meter in length, min 4 nos of bars from different bundles.

Measure the length of cut bars by measuring it on at-least 4 sides and average out the length of bar.

Weight the bar on weight scale and record it in register.

Calculate the actual average weight per meter of bar for at-least 3 samples.

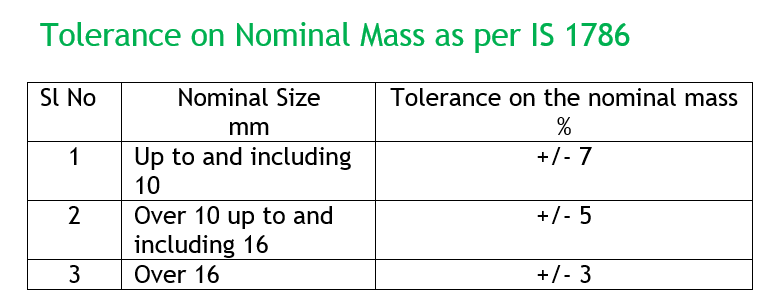

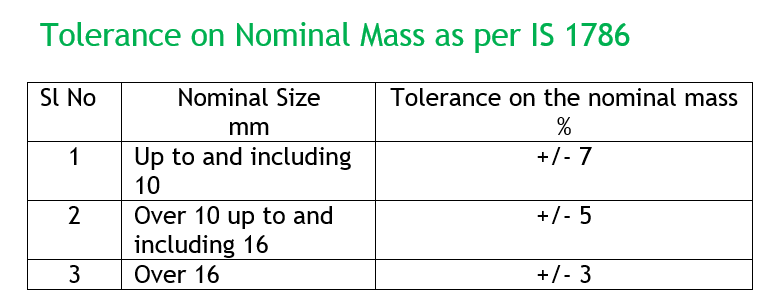

Compare the result of it with theoretical weight given in IS 1786

Check the variation in weight is within limit or not as per IS specification.

After finding the results for nominal mass as satisfactory proceed further to do bend test.

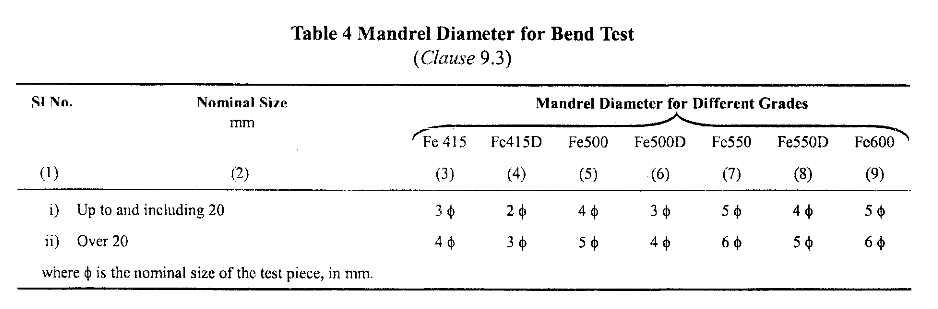

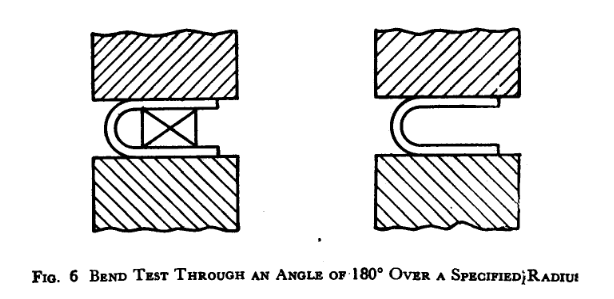

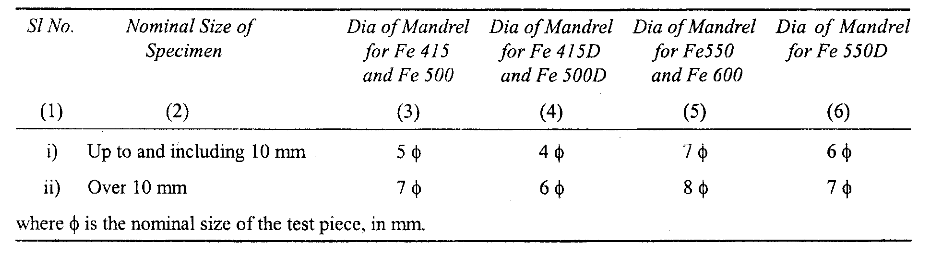

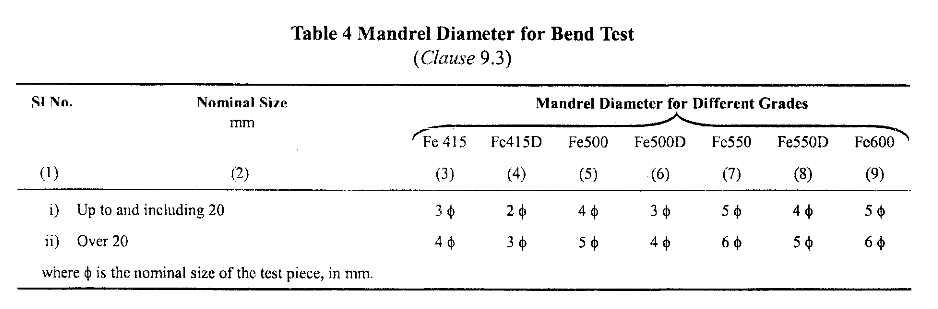

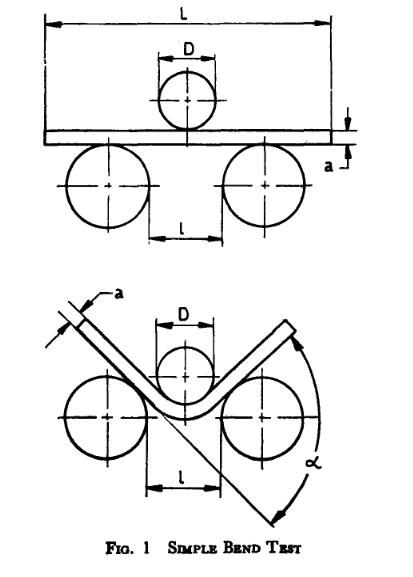

Bend test should be carried out as specified in IS 1599 and using mandrels of size specified in IS 1786

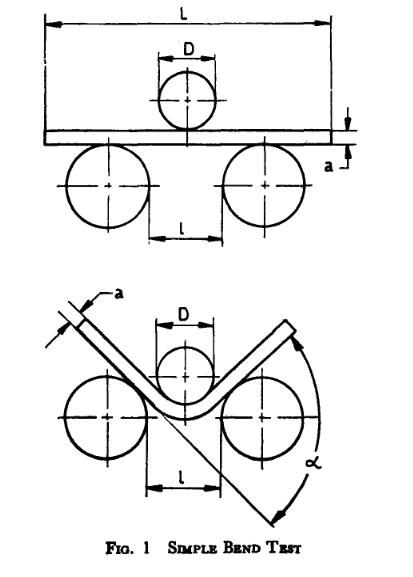

Rebar sample should be bent at 180 degree as per procedure stated in IS 1599.

after this further process it to bend till 180 degree.

At site we can bend it on bar bending machine using appropriate size mandrel.

sample tested bar.

After bending the bar check the surface of bar opposite to bend side (which got tension, elongated due to bending) for cracks and rupture visible to a person with normal or corrected vision.

If there is no sign of rupture and cracks, rebar meets the requirement of bend test.

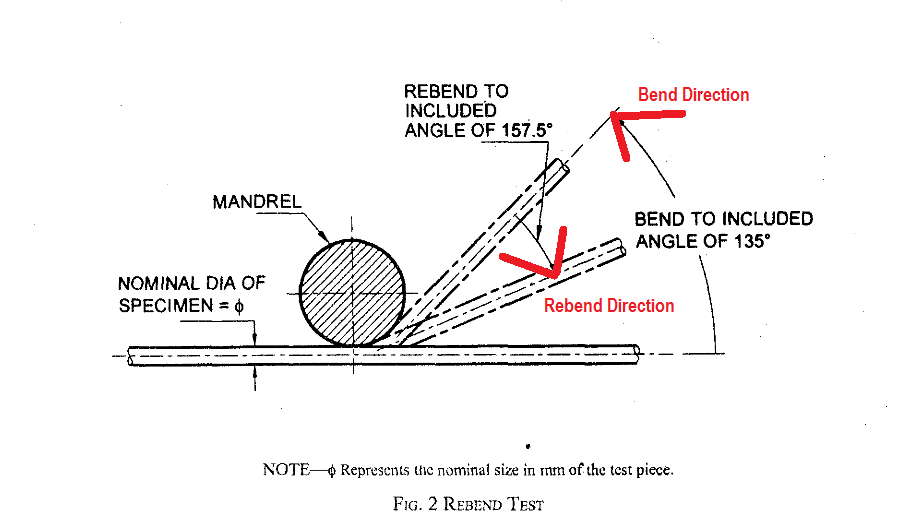

Further to this a rebend test also can be done at site, if required. (IS specifies for doing but if it passes bend test, in general it will pass the rebend test too. You cand do it at side provided you have required arrangement at site for this test)

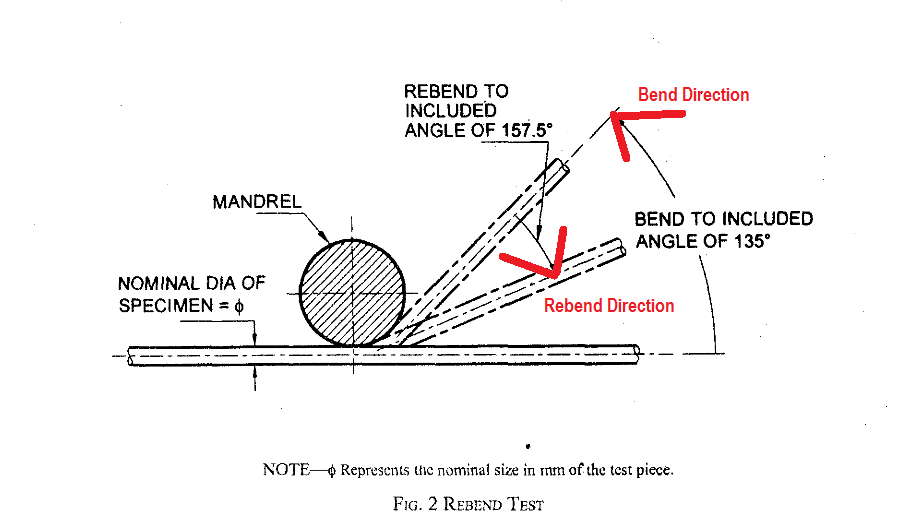

For Rebend Test

First bend the bar to including angle of 135 degree.

Keep it in boiling water at 100 degree for 30 minutes.

Then cool it down for some time.

After cooling bent it back to including angle of 157.5 degree

The rebar should not show any rupture or cracks to a person with normal or corrected vision.

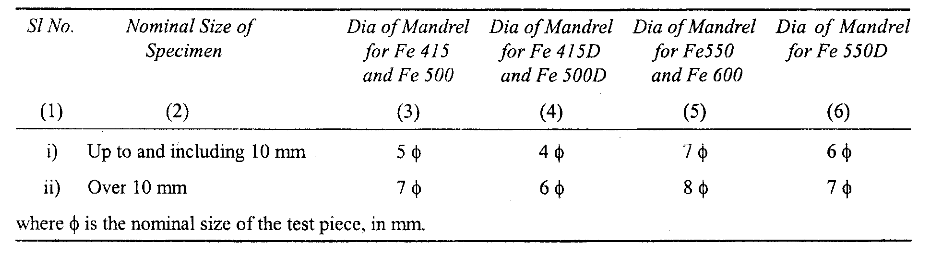

Mandrel to use for Rebend test as specified in IS 1786

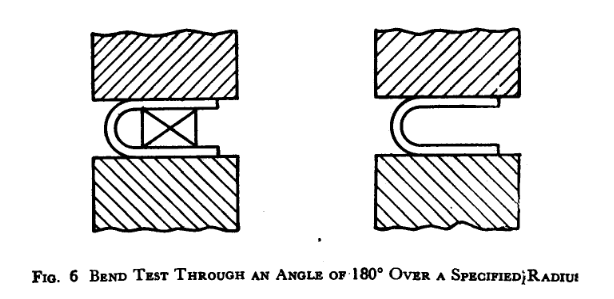

Below is pic showing bend rebend test (Closely look at the direction of bending and re-bending, in order to do correct test)

After getting satisfactory results, you can approve the steel for further usage in actual construction.

Keep practice of getting steel tested from third party laboratory at 200 metric tone or at each lot received which ever is acceptable for your management.

I personally did a bend and rebend test for 25mm and 32 mm bar by witnessing it in third party laboratories.

When steel failed at my site and got passed in multiple third party test.

When i did witness test, i shocked to see many laboratories don't have the equipment's to test it, as their current set up don't allow higher diameter bars to get bend and rebend test.

Either machine reach its maximum capacity or their is chance of accident if we do it as per specification (That same laboratories gave me report stating rebar failure, this is real condition at least in my area of NABL accredited labs)

So my suggestion to all, when you get doubt on quality of steel, you personally witness the test process to understand either steel passes the test or not.

To do value addition to company and your self, you can implement following practice during unload of steel at site;

Count the number of bars received.

Record the average length of bar by doing random measurements.

Calculate the actual weight of steel received as per theoretical weight and compare it with actual total weight.

Make comparative statement showing the variation in steel weight as per brand of steel.

Show it to your management which brands are supplying overweight steel.

Overweight steel though it is as per tolerance provided in IS 1786 will cause a loss of money to your company, by understanding the which steel brand manufacture to optimum level and produce less overweight steel you can reduce the indirect loss to your company.

If i receive 25mm steel with 3% over weight, technically there is nothing wrong. Steel meets the requirement of IS 1786.

Site will suffer for 3% wastage without actually wasting steel and waste count will always add this unaccounted 3% loss as wasted by site engineer unless it is recorded.

Saving those 3% may cause gain of crores of rupees which are going directly to pocket of supplier and causing indirect costs to project due to which site engineers suffers a lot to get promotion. It may help you to get up in your career.

This is just a one example of steel, if you do correct work you can save a lot to company and get return benefit for doing such jobs.

This is something comes from experience and not told in any books (Now a days i wont read book, if any author had catched it then i am not aware about it, to write something like this author should have practical experience of project )

)

Hope this will help you in doing better testing of steel bars and satisfaction of doing it right.

We do not charge for replying to this thread nor to become a registered member.

You can always reply to thread with whatever you have to say. Even you can correct someone by replying, if you feel shared content is wrong.

This gives opportunity for content author to correct himself if he did some wrong, Also help others to learn a correct thing.

When a lot of steel received at site, First check the Manufacturer test certificate for its actual properties.

With each lot of steel, manufacturer should send a test certificate of same lot for test done at their laboratory.

Check for grade of steel mention in certificate and is as per the order or not.

Steel bars may have rusting on it, do check closely to know either it is acceptable or not.

Steel received should be free from any contamination like, mud, dust, oil and any other foreign material etc.

Bars should not have splits and any other deformation on it.

Causes of Rusting:

Primary steel which is made from pure iron ore are likely to get rusted quicker compare to secondary steel.

Bars may get rusted due to contact with water or air and atmospheric condition.

A brownish bars showing little rusting due to weathering are good for use.

Small amount of rust is good for bonding of steel and concrete.

If excessive scaling observed on the surface of bar, it should not be accepted.

Do Check for brand of steel, diameter and grade of steel embossed on steel bars.

Cut the samples of 1 meter in length, min 4 nos of bars from different bundles.

Measure the length of cut bars by measuring it on at-least 4 sides and average out the length of bar.

Weight the bar on weight scale and record it in register.

Calculate the actual average weight per meter of bar for at-least 3 samples.

Compare the result of it with theoretical weight given in IS 1786

Check the variation in weight is within limit or not as per IS specification.

After finding the results for nominal mass as satisfactory proceed further to do bend test.

Bend test should be carried out as specified in IS 1599 and using mandrels of size specified in IS 1786

Rebar sample should be bent at 180 degree as per procedure stated in IS 1599.

after this further process it to bend till 180 degree.

At site we can bend it on bar bending machine using appropriate size mandrel.

sample tested bar.

After bending the bar check the surface of bar opposite to bend side (which got tension, elongated due to bending) for cracks and rupture visible to a person with normal or corrected vision.

If there is no sign of rupture and cracks, rebar meets the requirement of bend test.

Further to this a rebend test also can be done at site, if required. (IS specifies for doing but if it passes bend test, in general it will pass the rebend test too. You cand do it at side provided you have required arrangement at site for this test)

For Rebend Test

First bend the bar to including angle of 135 degree.

Keep it in boiling water at 100 degree for 30 minutes.

Then cool it down for some time.

After cooling bent it back to including angle of 157.5 degree

The rebar should not show any rupture or cracks to a person with normal or corrected vision.

Mandrel to use for Rebend test as specified in IS 1786

Below is pic showing bend rebend test (Closely look at the direction of bending and re-bending, in order to do correct test)

After getting satisfactory results, you can approve the steel for further usage in actual construction.

Keep practice of getting steel tested from third party laboratory at 200 metric tone or at each lot received which ever is acceptable for your management.

I personally did a bend and rebend test for 25mm and 32 mm bar by witnessing it in third party laboratories.

When steel failed at my site and got passed in multiple third party test.

When i did witness test, i shocked to see many laboratories don't have the equipment's to test it, as their current set up don't allow higher diameter bars to get bend and rebend test.

Either machine reach its maximum capacity or their is chance of accident if we do it as per specification (That same laboratories gave me report stating rebar failure, this is real condition at least in my area of NABL accredited labs)

So my suggestion to all, when you get doubt on quality of steel, you personally witness the test process to understand either steel passes the test or not.

To do value addition to company and your self, you can implement following practice during unload of steel at site;

Count the number of bars received.

Record the average length of bar by doing random measurements.

Calculate the actual weight of steel received as per theoretical weight and compare it with actual total weight.

Make comparative statement showing the variation in steel weight as per brand of steel.

Show it to your management which brands are supplying overweight steel.

Overweight steel though it is as per tolerance provided in IS 1786 will cause a loss of money to your company, by understanding the which steel brand manufacture to optimum level and produce less overweight steel you can reduce the indirect loss to your company.

If i receive 25mm steel with 3% over weight, technically there is nothing wrong. Steel meets the requirement of IS 1786.

Site will suffer for 3% wastage without actually wasting steel and waste count will always add this unaccounted 3% loss as wasted by site engineer unless it is recorded.

Saving those 3% may cause gain of crores of rupees which are going directly to pocket of supplier and causing indirect costs to project due to which site engineers suffers a lot to get promotion. It may help you to get up in your career.

This is just a one example of steel, if you do correct work you can save a lot to company and get return benefit for doing such jobs.

This is something comes from experience and not told in any books (Now a days i wont read book, if any author had catched it then i am not aware about it, to write something like this author should have practical experience of project

Hope this will help you in doing better testing of steel bars and satisfaction of doing it right.

We do not charge for replying to this thread nor to become a registered member.

You can always reply to thread with whatever you have to say. Even you can correct someone by replying, if you feel shared content is wrong.

This gives opportunity for content author to correct himself if he did some wrong, Also help others to learn a correct thing.