Concrete is a composite made of different materials such as cement, aggregates, admixtures and water. It sets and hardens as a result of chemical reaction between the constituent materials. Curing is defined in (NRMCA CIP-11) as the maintaining of an adequate moisture content and temperature in concrete at early ages so that it can develop properties the mixture was designed to achieve. Curing begins immediately after placement and finishing so that the concrete may develop the desired strength and durability.

The primary aim of curing is to prevent the loss of moisture from fresh concrete due to evaporation and to maintain the immature concrete moist for a suitable time until it most of hydration reactions have been taken out has attained the desired strength and hardness.

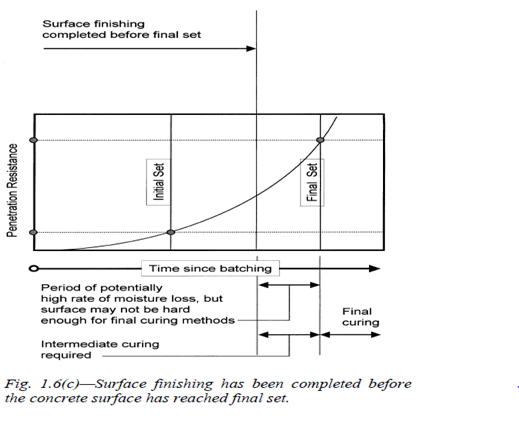

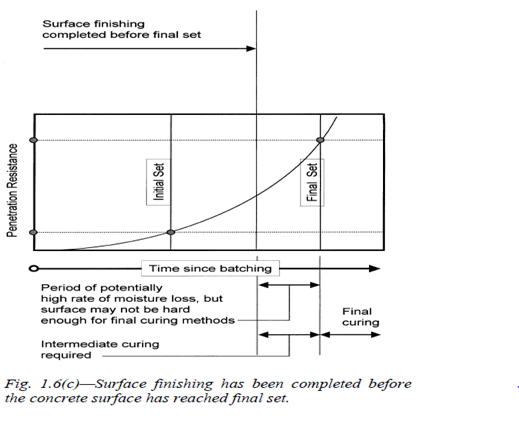

Concrete Curing should start as soon as the placing and finishing process is done (initial Curing) as if the concrete left without curing it will shrink as it dry due to surface tension of the water, drying shrinkage cracks will get developed at the surface of concrete.

ACI 308 Guide to Curing Concrete

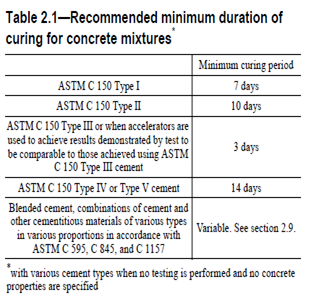

Curing temperature also is an very important issue specially within mass concrete applications The curing period may depend on the properties required of the concrete, the purpose for which it is to be used, and the ambient conditions, i.e the temperature and relative humidity of the surrounding atmosphere.

ACI 308 Guide to Curing Concrete

Curing is designed primarily to keep the concrete moist, by preventing the loss of moisture from the concrete during the period in which it is gaining strength. Curing may be applied in a number of ways and the most appropriate means of curing may be dictated by the site or the construction method.

EFFECT OF DURATION OF CURING ON PROPERTIES OF CONCRETE

The strength of concrete is affected by a number of factors, one of which is the length of time for which it is kept moist ” cured“.

Figure 1 illustrates this, comparing the strength (at 180 days) of concrete for which the surfaces have been:

Even three days water curing increases this figure to 60%, whilst 28 days water curing increases it to 95%. Keeping concrete moist is therefore, a most effective way of increasing its ultimate strength.

Concrete that is allowed to dry out quickly also undergoes considerable early age drying shrinkage. Inadequate or insufficient curing is one of main factors contributing to weak, powdery surfaces with low abrasion resistance. The durability of concrete is affected by a number of factors including its permeability and absorption.

Broadly speaking, these are related to the porosity of the concrete and whether the pores and capillaries are discrete or interconnected.

Whilst the number and size of the pores and capillaries in cement paste are related directly to its water-cement ratio, they are also related, indirectly, to the extent of water curing. Over time, water curing causes hydration products to fill, either partially or completely, the pores and capillaries present, and, hence, help to reduce the porosity of the paste.

Considerations for selecting a curing method

The primary aim of curing is to prevent the loss of moisture from fresh concrete due to evaporation and to maintain the immature concrete moist for a suitable time until it most of hydration reactions have been taken out has attained the desired strength and hardness.

Concrete Curing should start as soon as the placing and finishing process is done (initial Curing) as if the concrete left without curing it will shrink as it dry due to surface tension of the water, drying shrinkage cracks will get developed at the surface of concrete.

ACI 308 Guide to Curing Concrete

Curing temperature also is an very important issue specially within mass concrete applications The curing period may depend on the properties required of the concrete, the purpose for which it is to be used, and the ambient conditions, i.e the temperature and relative humidity of the surrounding atmosphere.

ACI 308 Guide to Curing Concrete

Curing is designed primarily to keep the concrete moist, by preventing the loss of moisture from the concrete during the period in which it is gaining strength. Curing may be applied in a number of ways and the most appropriate means of curing may be dictated by the site or the construction method.

- Curing by preventing excessive loss of moisture from the concrete either by :

- leaving formwork in place

- covering the concrete with an impermeable membrane after the formwork has been removed

- by the application of a suitable chemical curing agent (wax etc)

- or by a combination of such methods

- Curing by continuously wetting the exposed surface thereby preventing the loss of moisture from it either by :

- Spraying or fogging the surface with water are methods typically employed to this end.

- Submerge the concrete under curing water if possible.

EFFECT OF DURATION OF CURING ON PROPERTIES OF CONCRETE

The strength of concrete is affected by a number of factors, one of which is the length of time for which it is kept moist ” cured“.

Figure 1 illustrates this, comparing the strength (at 180 days) of concrete for which the surfaces have been:

- Kept moist for 180 days

- Kept moist for various periods of time and allowed to dry out

- Allowed to dry out from the time it was first made.

Even three days water curing increases this figure to 60%, whilst 28 days water curing increases it to 95%. Keeping concrete moist is therefore, a most effective way of increasing its ultimate strength.

Concrete that is allowed to dry out quickly also undergoes considerable early age drying shrinkage. Inadequate or insufficient curing is one of main factors contributing to weak, powdery surfaces with low abrasion resistance. The durability of concrete is affected by a number of factors including its permeability and absorption.

Broadly speaking, these are related to the porosity of the concrete and whether the pores and capillaries are discrete or interconnected.

Whilst the number and size of the pores and capillaries in cement paste are related directly to its water-cement ratio, they are also related, indirectly, to the extent of water curing. Over time, water curing causes hydration products to fill, either partially or completely, the pores and capillaries present, and, hence, help to reduce the porosity of the paste.

Considerations for selecting a curing method

- General

- Type of member

- Is the member vertical or horizontal? Some methods are affected or excluded by orientation.

- Is the member thin or thick? Thick sections such as large columns or mass concrete are mostly ‘self-curing’ but require temperature gradient at outer layers to be limited.

- Is the member insitu or precast? Precast members are suited to low-pressure steam curing while precast products may benefit from autoclaving.

- Environment

- Does the location affect the availability or cost of some curing materials? Like the availability of water in an arid region.

- Is the weather likely to be hot or cold? If the temperature is higher than 30°C or less than 10°C special precautions need to be taken.

- Is the site exposed to winds? If so, special precautions may be required to prevent plastic shrinkage cracking; sprinkling methods may be affected; or extra care required when using plastic sheeting.

- Impermeable membrane curing

- Retention of formwork

- What is the effect on site operations and construction cycle schedule?

- Is there likely to be cold weather? This method allows easy addition of insulation.

- Is uniform concrete colour specified? If so, a constant stripping time will need to be maintained to avoid hydration colour change.

- Plastic sheeting

- What is the effect on access and site operations?

- Is there a safety consideration? Plastic sheeting may be slippery, and is therefore a hazard in horizontal applications.

- Is there likely to be hot or cold weather? Colour of sheeting should be selected to suit.

- Is the situation such that the seal can be maintained with minimum risk of holing.

- Is uniform concrete colour specified? If so, the sheeting must be kept clear of the surface to avoid hydration staining.

- Curing compounds

- What are the manufacturer’s recommendations? Both the rate of application and the timing are critical for effectiveness. Does the product comply with

- Standard specifications.

- What is the concrete surface texture? Coarse textures require higher application rates.

- Can a uniform application be achieved in the particular situation? Two applications at right-angles help. Sites exposed to wind create problems.

- Is there likely to be hot or cold weather? A suitably pigmented compound can help.

- Are there to be applied finishes (render, tiles, etc)? Residue from compounds can affect the ‘bond’ of later applied finishes.

- Is there a health consideration? Compounds may be toxic, and their use in enclosed situations may therefore be hazardous.

- Water curing

- Ponding

- What is the effect on access and site operations?

- Is suitable ‘dam’ material available? A clay soil is the most suitable.

- Is there likely to be hot weather? Ponding is an efficient means of maintaining a uniform temperature on slabs.

- Is concrete colour or appearance a consideration? ‘Dam’ materials, particularly clay, tend to stain.

- Sprinkling

- What is the effect on site operations?

- Is there an adequate water supply?

- What is effect of run-off? Usually some form of drainage is required.

- Will required volume/timing be such as not to damage the concrete surface?

- Can application be maintained continuously? Intermittent wetting and drying can be deleterious.

- Is site exposed to winds? This makes continuous application very difficult.

- Wet coverings

- What is the effect on site operations?

- Can they effectively cover all surfaces?

- Is site exposed to wind? Wet coverings are easier to keep in place than plastic sheeting.

- Is concrete colour or appearance a consideration? If so, sand should have low clay content; fabrics and water should contain no impurities.

- In the case of sand, its supply or removal a problem?

- Can coverings be kept continuously moist? Intermittent wetting and drying can be deleterious.