Concrete is the foundation of contemporary infrastructure. From buildings to roads, its strength dictates the safety and duration of structures. Out of different methods of quality control, concrete cube testing is the most commonly accepted and used method. Let's discuss why this simple test is still the gold standard in construction.

The test is carried out according to IS 516 in India, or equivalent international practice, to check the concrete for fulfilling the specified strength grade.

Cube testing of concrete gives a direct reading of the hardened concrete's compressive strength, guaranteeing the mix design and batching process meet the required performance.

2. Adherence to Standards

The test is usually obligatory in any project in order to comply with IS code requirements and contract stipulations. Cube test results are utilized by engineers, contractors, and quality control laboratories to approve structural safety.

3. Early Detection of Problems

Routine cube testing facilitates the detection of defects like poor batching, poor curing, or improper water–cement ratios prior to their deteriorating the entire structure.

Concrete Compressive Strength (MPa) = Maximum Load (N) / Cross-Sectional Area (mm²)

Concrete cube testing remains the benchmark in construction since it balances precision, cost-effectiveness, and global acceptance. Although new methods such as ultrasonic pulse velocity (UPV) and rebound hammer tests are fast, cube testing stands alone in demonstrating the concrete's actual compressive strength. To engineers and constructors, it is not a test but the standard of quality and safety in construction.

Also Read:

civil4m.com

civil4m.com

civil4m.com

civil4m.com

civil4m.com

civil4m.com

civil4m.com

civil4m.com

What is Concrete Cube Testing?

Concrete cube testing is one of the procedures to establish the compressive strength of concrete by curing cubes of a fixed size in controlled laboratory conditions and subsequently testing them in a Compression Testing Machine (CTM).The test is carried out according to IS 516 in India, or equivalent international practice, to check the concrete for fulfilling the specified strength grade.

Significance of Concrete Cube Testing in Construction Industry

1. Quality AssuranceCube testing of concrete gives a direct reading of the hardened concrete's compressive strength, guaranteeing the mix design and batching process meet the required performance.

2. Adherence to Standards

The test is usually obligatory in any project in order to comply with IS code requirements and contract stipulations. Cube test results are utilized by engineers, contractors, and quality control laboratories to approve structural safety.

3. Early Detection of Problems

Routine cube testing facilitates the detection of defects like poor batching, poor curing, or improper water–cement ratios prior to their deteriorating the entire structure.

Procedure for Concrete Cube Test

- Sample Preparation – Fresh concrete is filled in 150 mm x 150 mm x 150 mm cube moulds in three layers, and each layer is tamped 35 times.

- Curing – The cubes are kept in a curing tank at 27 ± 2°C for the given duration (typically 7 and 28 days).

- Testing – Cured cubes are put into the CTM, and load is applied uniformly up to failure.

Calculation of Concrete Compressive strength :

Concrete Compressive Strength (MPa) = Maximum Load (N) / Cross-Sectional Area (mm²)

Why Concrete Cube Testing is Still the Gold Standard

1. Simplicity and Reliability

In contrast to sophisticated non-destructive techniques, cube testing involves little equipment and training but produces extremely precise results.2. Globally Accepted

Cube test reports are embraced by clients, consultants, and regulatory authorities across the globe whether it is a small housing project or large infrastructure project.3. Economical

The test is low-cost compared to high-tech options, and it suits projects of any size.4. Reference Against Historical Data

Since cube testing has been done for decades, engineers can compare against a huge database of previous works to forecast performance.Disadvantages of Concrete Cube Testing

- Results are only for the cube sample and not for the entire construction.

- It is a destructive test since the sample is wasted after testing.

- Results only become available after curing (7 or 28 days), potentially behind decisions.

- Despite such constraints, no other technique has the balance of cost, accuracy, and acceptability of cube testing.

Best Practices for Reliable Concrete Cube Testing

- Adopt IS 516 for casting, curing, and testing cubes.

- Utilize calibrated Compression Testing Machines.

- Provide proper curing temperature and moisture.

- Test several samples to compensate for variability.

Concrete cube testing remains the benchmark in construction since it balances precision, cost-effectiveness, and global acceptance. Although new methods such as ultrasonic pulse velocity (UPV) and rebound hammer tests are fast, cube testing stands alone in demonstrating the concrete's actual compressive strength. To engineers and constructors, it is not a test but the standard of quality and safety in construction.

Also Read:

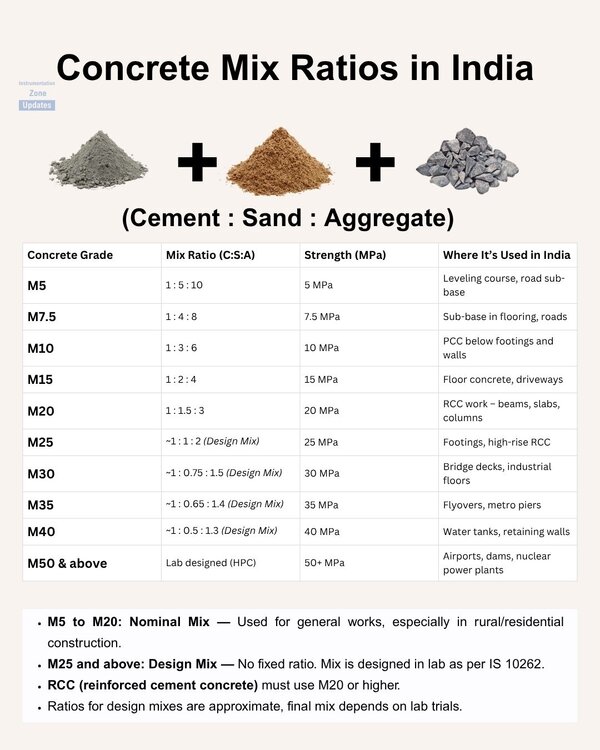

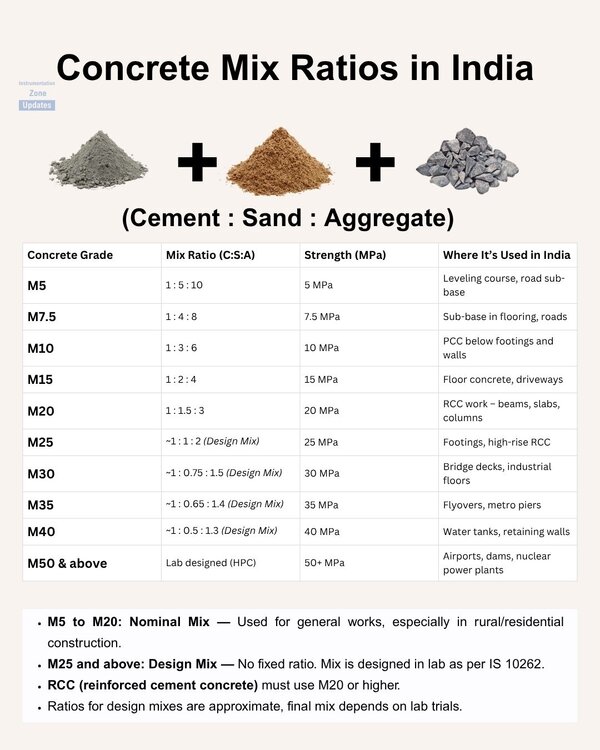

Understanding The Concrete Grades, Concrete Mix Ratios Applications, and Best Practices in India

Index Introduction What is a Concrete Mix Ratio? Understanding M Grades: What is M25 Grade of Concrete? Nominal Mix vs Design Mix Common Concrete Grades Used in India Concrete Mix Ratio Table (Cement:Sand:Aggregate) Applications of Various Grades – Regional Examples Importance of Choosing the...

Concrete Mix Ratio in India: Choose the Right Concrete Grade for Every Project

Concrete is the backbone of modern construction in India. From residential homes in Delhi to commercial projects in Gujarat and infrastructure works in Madhya Pradesh. But do you know what gives concrete its strength? It all comes from concrete mix ratio. Whether you’re a civil engineer, a...

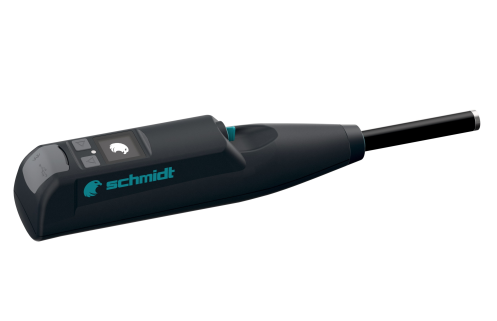

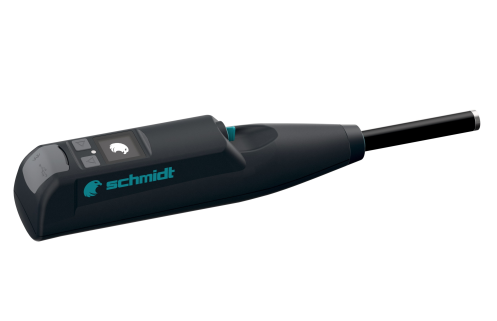

Rebound Hammer - The Quick Test to Know The Concrete Strength

🔎 What is a Rebound Hammer? A Rebound Hammer is a small, handy device used to check how hard and strong concrete is. It helps engineers test concrete without breaking it, which is why it's called a non-destructive testing tool. ⚙️ How Does Rebound Hammer Works? Rebound Hammer has a...

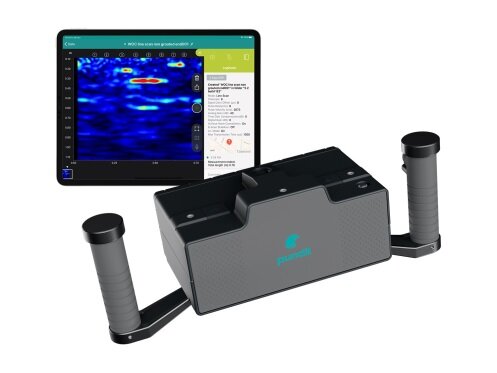

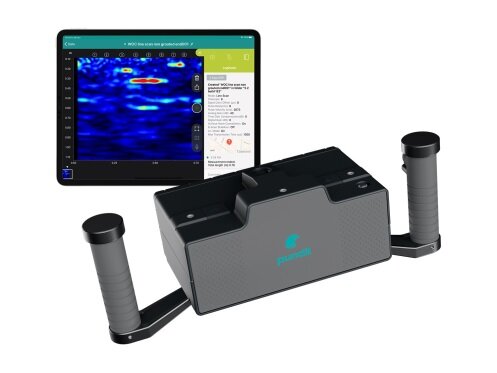

A Practical Guide for Ultrasonic Pulse Velocity (UPV) NDT Test for Concrete Quality in Indian infra projects

Concrete is a very popular material in Indian construction, which we see in large scale projects like that of bridges, tunnels and dams. As time goes by it is important to see to the durability and integrity of the concrete which in some cases may not be amenable to direct testing (like coring)...