Compressive Strength Test of Cement

Ref : IS : 4031 (part VI)

Purpose : To determine the compressive strength of cement

Significance : Compressive strength of cement helps in determining grade of cement, in

calculations of mix designing proportioning of concrete etc.

Apparatus:

Vibration machine

Poking rod

Cube mould of 70.6mm size

Gauging trowel

Balance, weights and tray

Graduated glass cylinder

Test Procedure:

Take cement 200gm, standard sand 600gm and water = (P/4 + 3.0) percent of combined mass of cement and sand, where P is the percentage of water required to produce a paste of standard consistency determined as described in IS 4031 (part IV) – 1988

Place mixture of above cement and sand (1:3) on a tray, mix it dry with a trowel for one minute and then with water (as per step (1) of procedure) until the mixture of uniform colour

Note: The time of mixing shall in any event be not less than 3 minutes and should the time taken to obtain a uniform colour exceed 4 minutes, the mixture shall be rejected and the operation repeated with a fresh quantity of cement, sand and water

Properly oil the interior faces and bottom of mould which should be water tight

Place the assembled mould on the table of vibration machine and hold it firmly in position by means of a suitable clamp. Attach a hopper of suitable size and shape securely at the top of the mould to facilitate filling and this hopper shall not be removed until the completion of vibration period

Immediately after mixing the mortar as in step (2) of procedure, place the mortar in the cube mould and rod with the poking rod 20 times in about 8 seconds to ensure elimination of entrapped air to prevent honey combing. Place the remaining quantity of mortar in the hopper of the cube mould and rod again as done for the first layer

Compact the mortar by vibration machine for 2 minutes at the specified speed of 12000 ± 400 vibration per minute

At the end of vibration, remove mould together with the base plate from the machine and finish the top surface of the cube in the mould by smoothening the surface with the blade of trowel

Keep the filled mould in moist cloth for 24 hours after completion of vibration

At the end of this period remove them from the mould and immediately submerge in clean fresh water

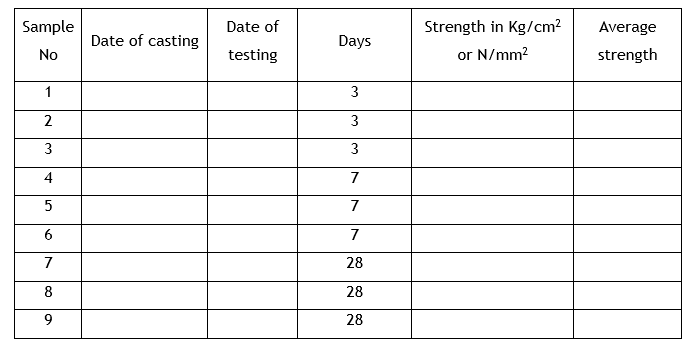

Test sets of three cubes for compressive strength at 3, 7 & 28 days in compression testing machine. The cubes shall be tested on their sides without any packing between the cube and the steel platens of the testing machine. Load shall be steadily and uniformly applied at the rate of 35 N/mm2 per minute

The load when the cube fails shall be noted and divided by cross sectional area of the cube and record the results.

Observation Table:

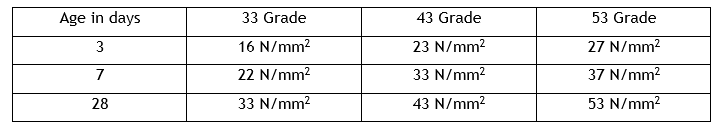

Limit: Minimum compressive strength in N/mm2 for different type of cement at different ages:

Frequency: For every batch received at site.